As China’s 2020 “Double 11” shopping festival wrapped up, e-commerce platforms reported a record-breaking surge in order volumes. On November 11 alone, billions of parcels were processed and delivered. JD Logistics, for instance, saw year-on-year growth across multiple business segments during the festival period: open-platform order volumes rose by 102%, individual parcel shipments surged by 164%, cloud warehouse shipments increased by 138%, and cold chain transportation volume doubled. The delivery of agricultural specialty products increased nearly fivefold compared to JD’s “618” mid-year sales event.

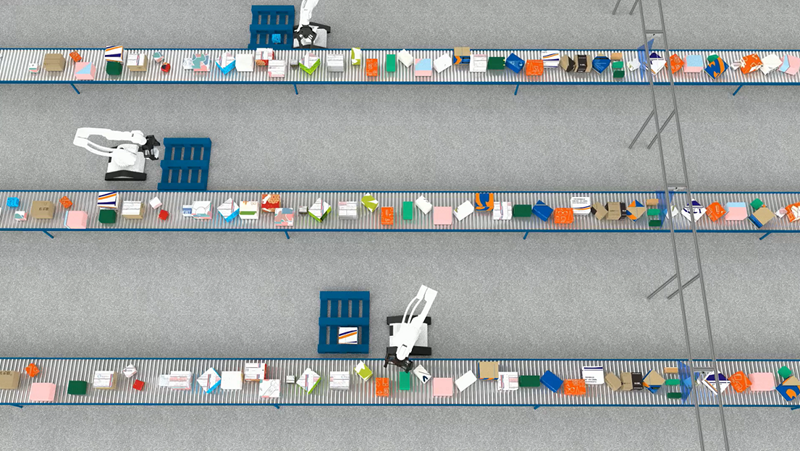

Despite this massive influx of orders, there were no reports of warehouse congestion or system overloads on social media or in the mainstream press. In fact, over half of the parcels were delivered on the same day. These numbers highlight the transformative impact of smart logistics technologies in China, which have now brought the country’s logistics industry to a globally leading level of efficiency—rendering warehouse backlogs a thing of the past.

Among the key technologies enabling this performance are high-speed automated sorting systems and advanced volume detection solutions, both of which have become critical components of modern logistics infrastructure. A standout contributor is Vizum’s next-generation smart logistics vision system. At the heart of this solution is Vizum’s proprietary “Natural Learning®”-powered Starlight Eye Bimetric Laser Stereo Camera, which outperforms similar products in the market and has been widely adopted by leading logistics companies.

Modern smart logistics increasingly demands highly accurate 3D information about packages during warehousing, sorting, and inventory management processes. For example, in automated high-speed sorting, conveyor belt speeds have advanced from under 1 meter per second to between 1 and 1.5 meters per second. Some of the most advanced logistics companies are now pushing for speeds as high as 2.5 to 4 meters per second. However, due to the limitations of conventional technologies and algorithms, only Vizum’s stereo vision solution is capable of supporting accurate 3D scanning at these speeds. After adopting Vizum’s ViEye system, these companies have seen a dramatic improvement in sorting throughput—from 3,000 to over 10,000 items per hour—achieving a 3- to 4-fold increase in efficiency and outpacing their competitors in shipment speed.

At the same time, the need for highly precise volume measurement is growing. Accurate package dimensions are essential for robotic arm vision positioning, optimizing storage and transport strategies, and calculating volume-based shipping costs. Traditional industrial cameras used in logistics typically have a margin of error of about 10mm. In contrast, Vizum’s ViEye stereo laser camera achieves a remarkable precision of just 1mm, making it the preferred solution for high-precision robotic picking and DWS (Dimensioning, Weighing, Scanning) applications.

As a vital part of the e-commerce ecosystem, the smart logistics sector continues to evolve rapidly. Vizum is committed to riding this wave of growth by launching increasingly competitive products. As demonstrated this year, its advanced technologies play a key role in ensuring that billions of Double 11 packages are delivered smoothly, without bottlenecks—and will continue to do so in the years ahead.