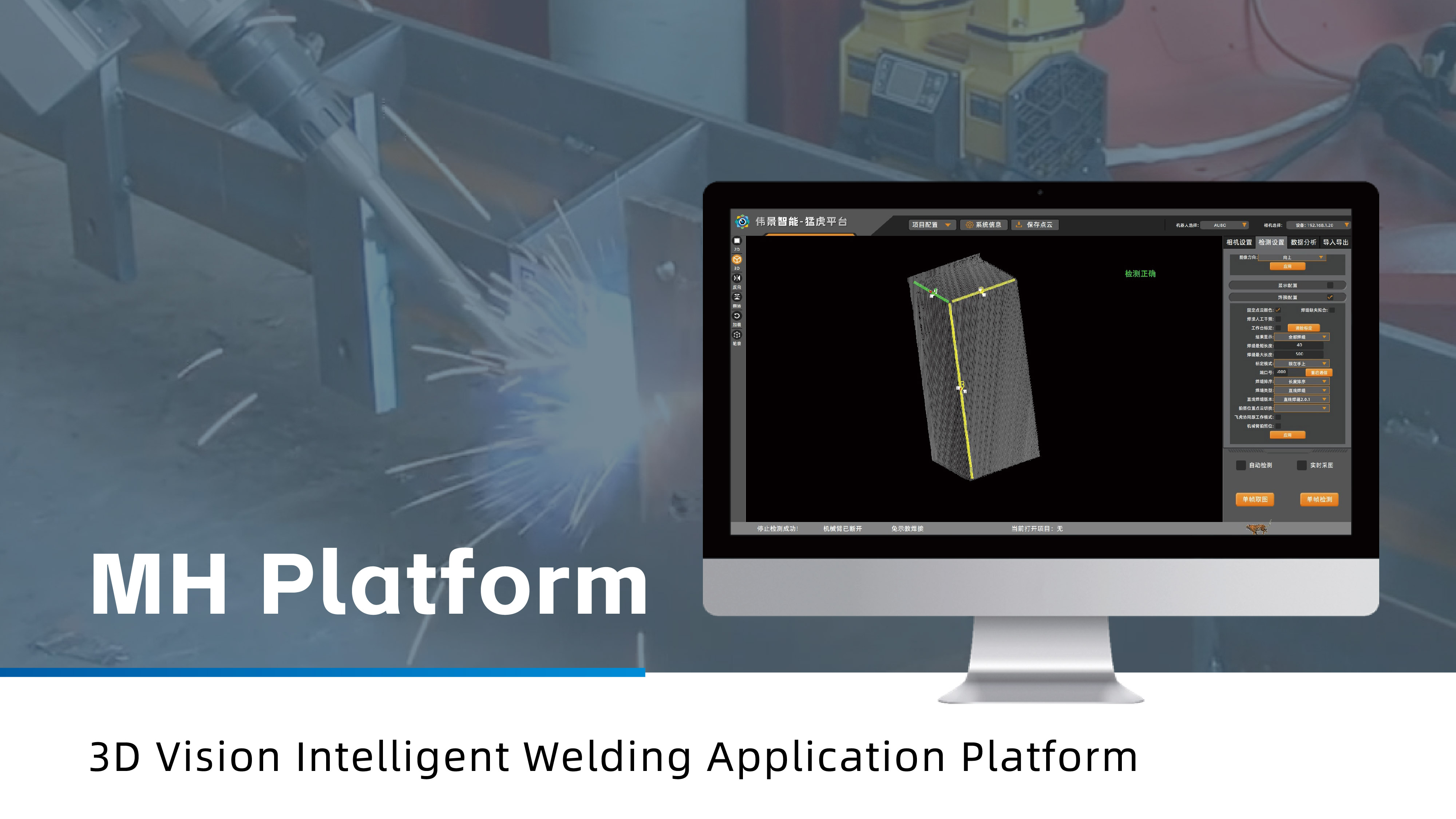

The 3D Vision Intelligent Welding Application Platform is powered by a high-performance, high-precision ViEye camera. It features workpiece template import and matching, intelligent recognition of linear, curved, and groove weld seams, multi-view panoramic fusion, intelligent weld path planning, and customizable welding process libraries. It enables welding robots to perform fully automated intelligent welding with a single click.

Solution Features

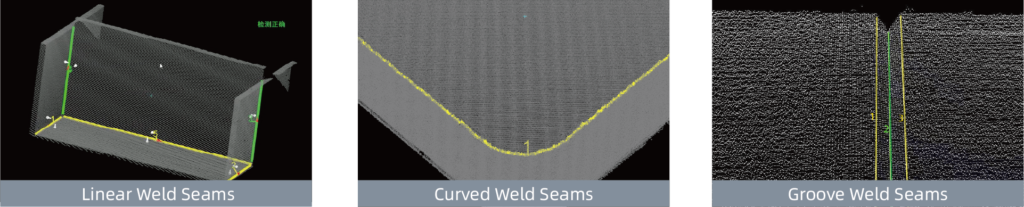

Supports Multiple Weld Seam Types: Accurate Recognition and Intelligent Extraction

Linear Weld Seams: Accurately identifies and extracts straight weld paths, ideal for standard linear welding tasks.

Curved Weld Seams: Advanced algorithms extract and adapt to complex or curved weld paths.

Groove Weld Seams: Precisely detects groove shapes and angles, matching them with the appropriate welding process.

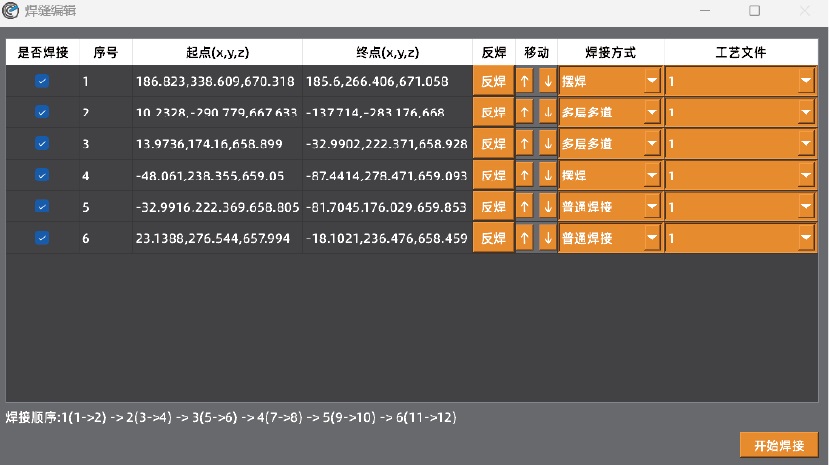

Customizable Welding Sequence and Process Parameters to Ensure Quality

Users can define welding sequences as needed to optimize pathing, improve efficiency, and reduce deformation and heat-affected zones. Each weld seam can be assigned different process parameters, such as straight welding, weaving welding, or multi-pass welding, ensuring optimal welding conditions.

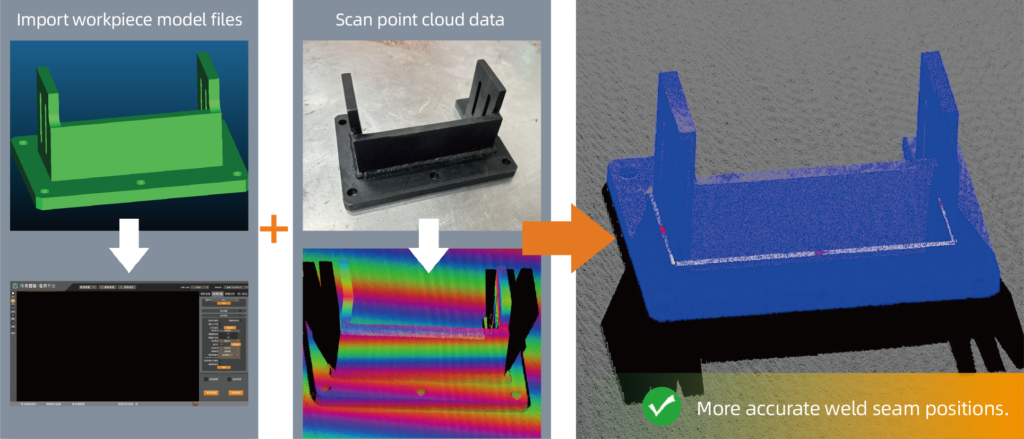

Supports Intuitive Learning and Efficient Reverse Modeling

With the template creation tool, users can import workpiece model files and annotate target weld seam locations. The platform automatically aligns the scanned point cloud data with the template file to extract more accurate weld seam positions.

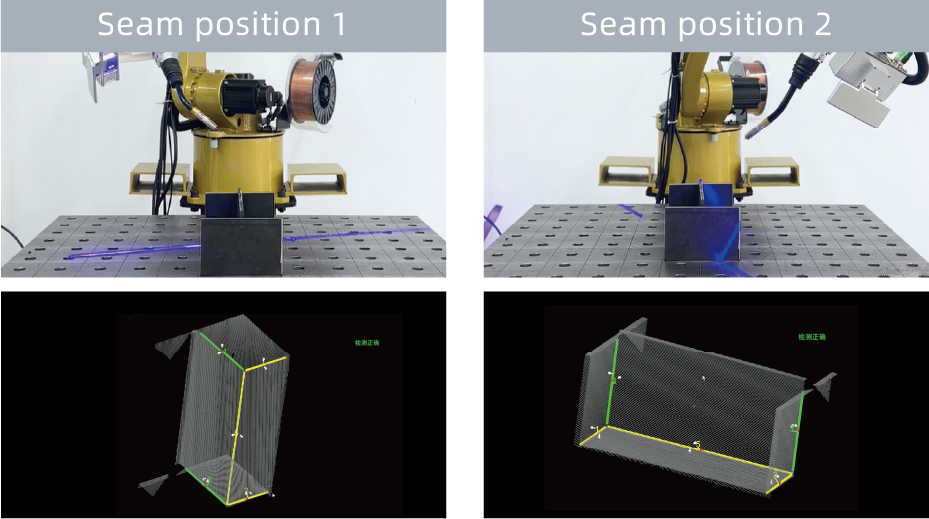

Multi-View One-Click Welding to Enhance Efficiency

Supports automated scanning and welding of double-sided or multi-faced workpieces with no manual intervention required. Ideal for complex welding scenarios such as various small and large-scale steel structures, significantly boosting productivity and optimizing operations.

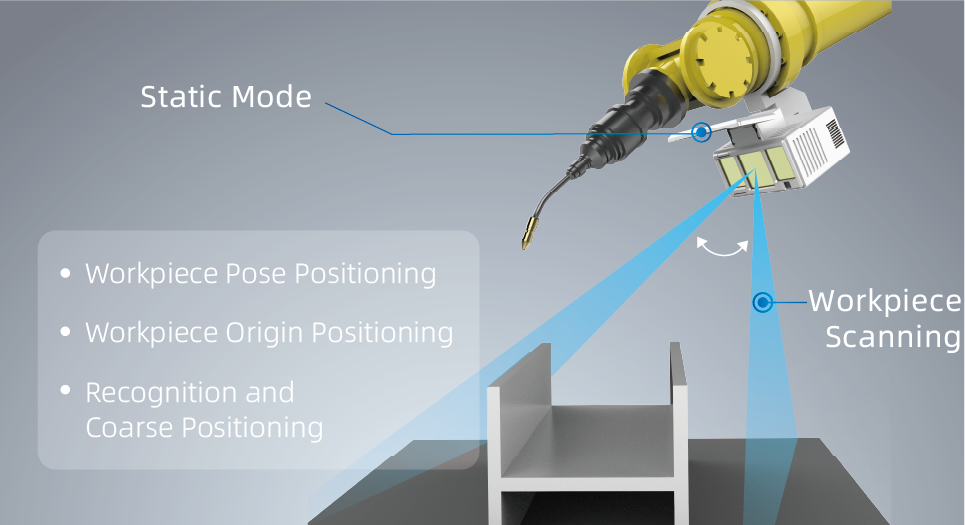

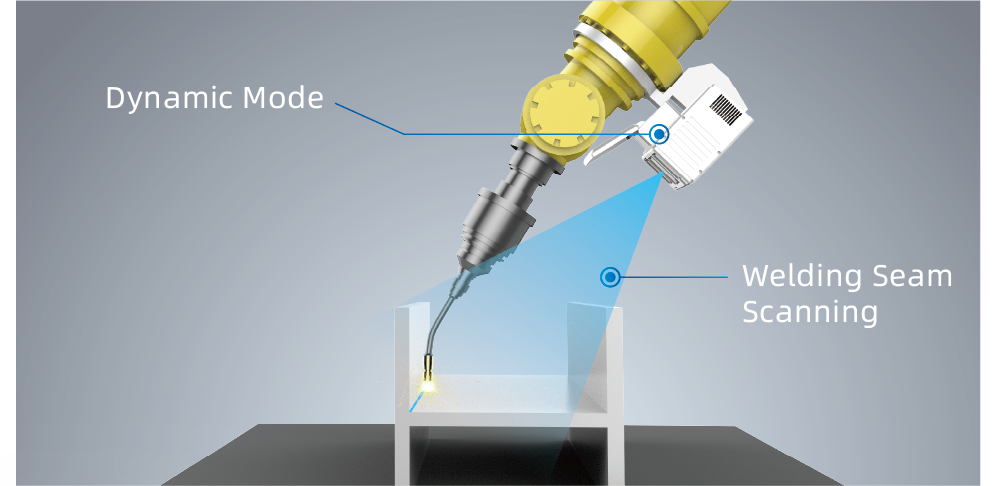

Supports Dynamic and Static Switching for Better Cost-Performance Ratio

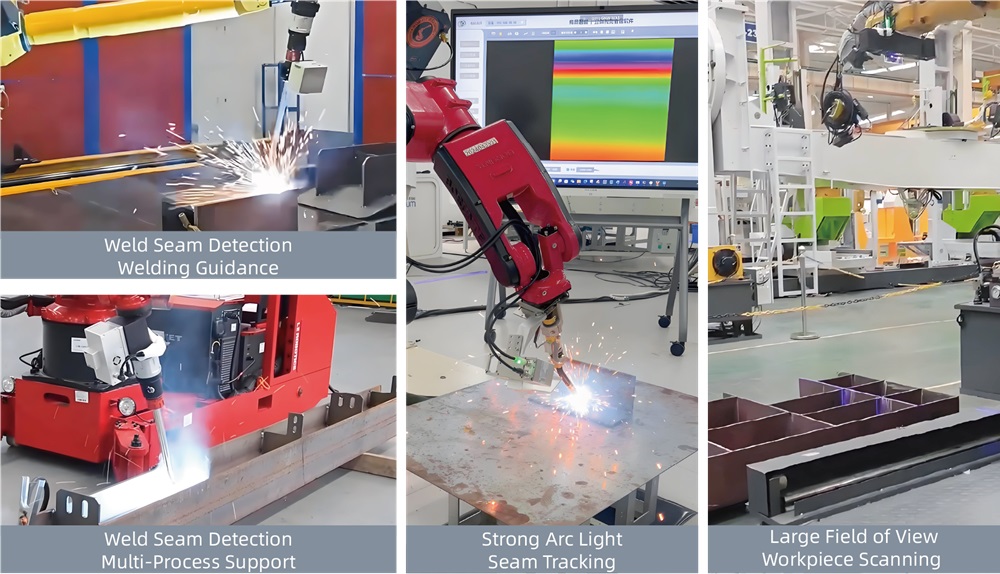

Supports weld seam tracking, enabling real-time scanning and quality monitoring during welding. Dynamic/static mode switching via software allows a single camera to handle both weld extraction and tracking. The all-in-one design improves control precision and efficiency while reducing hardware costs, offering an excellent cost-performance ratio.

Compatible with Various Workpiece Types

Supports a wide range of workpiece configurations including H-beam welding, profile-to-plate welding, rebar welding, pipe arc welding, circular seam welding, and straight-line plate welding.

Compatible with Dozens of Industrial Robot Brands

Fully compatible with major domestic and international robotic arms including ABB, Yaskawa, KUKA, Nachi, Panasonic, FANUC, Kawasaki, AUBO, Han’s Robot, STEP Electric, EFORT, Paiten, Rokae, Qianjiang Robot, Estun, Siasun, JAKA Robotics, Borunte, and MoCa. and more.

Application Scenarios