Logistics Volume Measurement and Quantity Statistics System

System Overview

The Logistics Volume Measurement and Quantity Statistics System utilizes stereo vision technology to acquire the 3D spatial coordinates of objects. It enables high-speed measurement of package dimensions (length, width, height), cumulative volume calculation, object counting, pose estimation, and localization of object center and corner points. This system meets the needs of enterprise data management, quantity statistics, and intelligent sorting. It is widely applicable across various fields, including industrial manufacturing logistics, warehouse management logistics, express parcel logistics, maritime and shipping logistics, agricultural produce logistics, and food and pharmaceutical packaging logistics.

System Features

- Intelligent Terminal: Directly outputs functional data results from the camera.

- Low Latency: Data acquisition, processing, and transmission delay are all under 10ms.

- Thin Object Detection: Measurement accuracy is under 1mm for a 1-meter width and under 3mm for a 2-meter width, allowing detection of thin items such as envelopes and small packages.

- Large Depth of Field and Wide Field of View: The camera’s field of view can reach up to 3 meters in width, with a depth of field of up to 1.5 meters.

- Supports High-Speed Motion: Meets real-time processing requirements for applications at speeds of up to 6m/s with millimeter-level accuracy.

- Multiple Triggering Modes Supported: Includes software trigger, pulse trigger, level trigger, and other working modes.

- Contact Object Segmentation: Capable of segmenting and measuring contact-based objects, ensuring accurate measurements for each package.

- Supports Complex Scenarios: Works with mixed black-and-white, multi-color, absorbent, reflective, and varying lighting conditions for simultaneous package detection.

- One-Click Guardrail Calibration: The one-click calibration function filters out unwanted data from guardrails and conveyor belts.

- Adaptive Conveyor Belt: Features a one-click horizontal calibration function to address issues such as inclined, uneven, or minor vibrations in the conveyor belt.

- No Need for Infrastructure Modification: The system can be installed directly above the existing conveyor belt without requiring any changes to the current operational environment.

- Industrial Grade Standards: Rated to industrial IP65 standards and uses aviation-grade connectors with Gigabit Ethernet for data transmission.

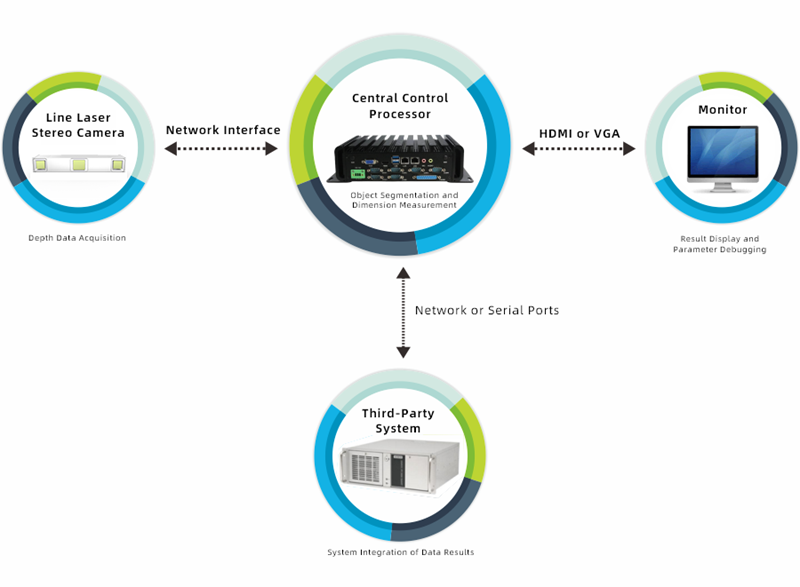

System Communication Diagram

System Applications

Industry Applications