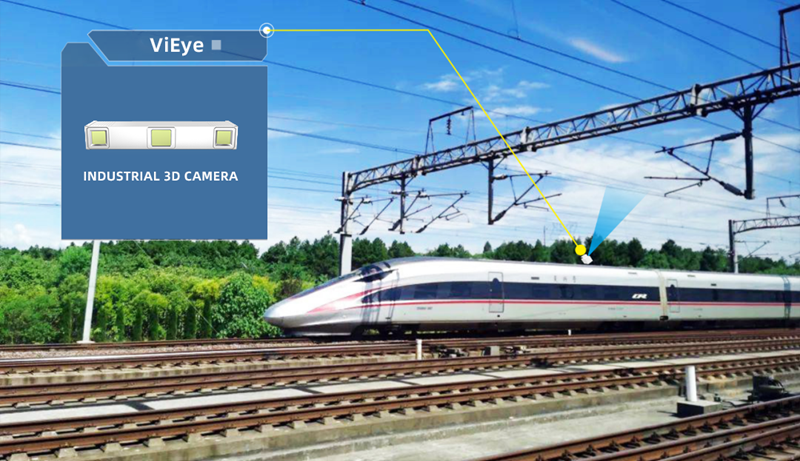

High-speed Rail Stringing Detection Specialized Vision Sensor

System Overview

The suspension wire detection auxiliary positioning solution uses stereo vision cameras combined with Vizum’s proprietary natural learning algorithm. This system can accurately capture and identify the presence or absence of suspension wires on the conveyor belt, filtering out interference. It ensures stable recognition in both strong light and dim environments, with a fast recognition speed (around 10ms). The system does not require additional industrial control computers; the cameras themselves directly provide trigger signals to activate the image capture system and capture suspension wire images.

System Features

- Embedded Algorithm: Can directly output result data for integration with third-party systems or PLCs.

- Terminal Intelligence: No need for industrial control equipment; the camera has its own processor and can complete detection independently.

- Low Processing Latency: Line scan point cloud data output is less than 1ms, and application result calculations are output in less than 10ms.

- High Precision: The maximum detection precision can reach 3um.

- Supports High-Speed Motion: Can handle real-time processing requirements for a 360 km/h moving conveyor belt.

- Supports Variable Speed Motion: Supports the integration of external pulse encoder signals and speed interface soft trigger docking.

- Strong Environmental Adaptability: Works normally in both indoor and outdoor environments, including dim lighting.

- Adaptable to Various Complex Scenarios: Capable of high-precision 3D reconstruction for reflective and light-absorbing objects.

- Industrial-Grade Design: Features aerospace plug connectors, IP67-rated enclosure design, and meets industrial usage requirements.

System Communication Diagram