ViEye Industrial-Grade Line Laser 3D Camera

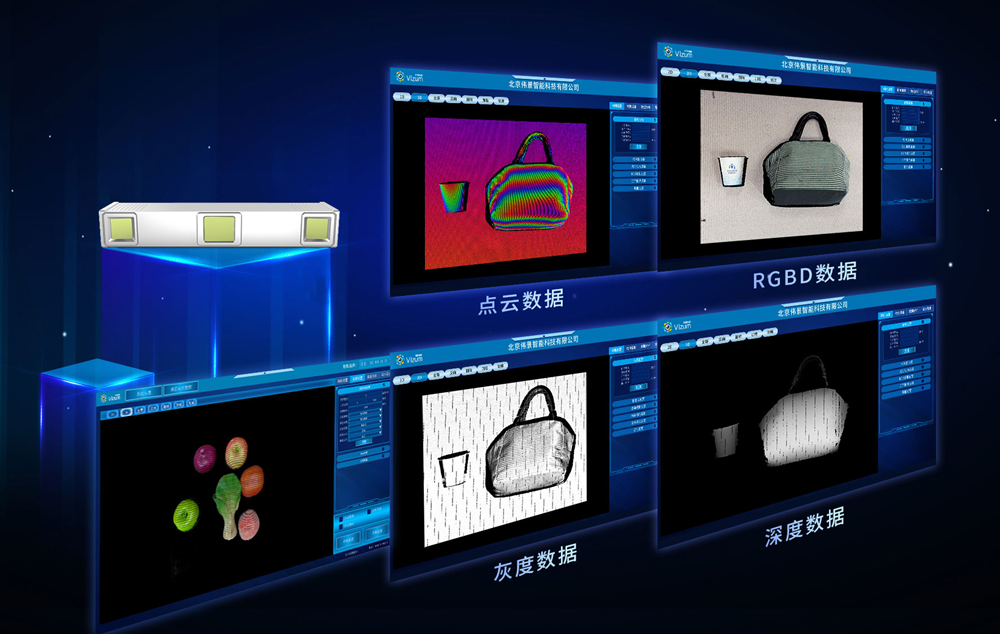

ViEye® industrial-grade line laser 3D camera adopts an intelligent terminal architecture, capable of directly generating point cloud models, RGBD data, depth maps, grayscale images, and color images at the device level. It demonstrates strong performance in scenarios involving high-speed motion, high ambient light, reflective surfaces, and both indoor and outdoor environments. The camera supports embedded deployment of various intelligent algorithms, enabling applications in 3D localization, flow monitoring, object measurement, and surface inspection across a range of industrial use cases.

Product Features

Standard Output Functions of the Camera

- Point Cloud Data Output (Digitized XYZ coordinates)

- RGBD Data Output (Color point cloud with spatial coordinates)

- Depth Map Output

- Grayscale Image Output

- Color Image Output

Software Functions

- Visualization Interface

Hand-Eye Calibration Software Service - Remote Communication IP Configuration

- Remote Parameter Tuning

- Open SDK Interface with Demo Integration Support

- Flexible Integration of Various Application Algorithms

Resistant To Strong Light And Reflections; Adaptable To Various Complex Environments

- Supports high-precision modeling under 480,000 Lux strong light environments

- Supports noise-free modeling of reflective and polished object surfaces

- Supports defect-free modeling of black light-absorbing materials on object surfaces

Terminal Intelligence, Enabling Easier Implementation and Deployment

- Embedded with high-performance processing chips, the camera outputs result data directly at the frontend

- Factory-calibrated intrinsic parameters, enabling quick implementation and deployment for convenience

- Direct integration with user industrial PCs or PLCs, offering faster real-time efficiency

Large Depth of Field and Wide Field of View, Meeting the Requirements of Various Application Scenarios

- The ViEye camera with large pupil distance achieves a 2m scanning depth of field

- Single camera line scan width can reach up to 5m

- Supports multi-camera fusion to extend the detection field of view

Equipped With A Splash-Proof Shield To Better Handle The Challenges Of Real Industrial Environments

- Aerospace connector, IP65 protection rating

- Equipped with a splash-proof shield, more suitable for high temperature, welding, and other scenarios

High Precision, High Frame Rate, and Detailed Data Management

- Uses a high-resolution image sensor, with a single line point cloud count up to 4096

- Utilizes a global exposure chip, with a maximum line scan rate of 6000 lines/s

- Achieves micron-level spatial positioning accuracy, meeting the demands of detailed scene detection

Diverse Model Options to Meet the Demands of Various Scenarios

- Camera pupil distance can be selected based on different installation heights

- Camera lenses can be selected based on varying scanning fields of view

- Camera material and size can be selected based on different installation methods

- Line scan or area scan modes can be chosen based on dynamic and static scene requirements

Quick Calibration, Flexible and Versatile

- Fast hand-eye calibration ensures consistency between the camera and robotic arm’s spatial coordinate systems

- For large part grinding and welding, the camera does not need to be mounted on the robotic arm and can be fixed in place

- Multiple camera stitching can be used to meet the needs for a larger field of view in positioning

Compact and Lightweight Design, Easy for Robotic Arm Installation

- Minimum dimensions 1608063mm, weight around 1kg, suitable for flexible robotic arm installation

- Compact structure with regular shape, facilitating robotic arm motion planning

Application Scenarios

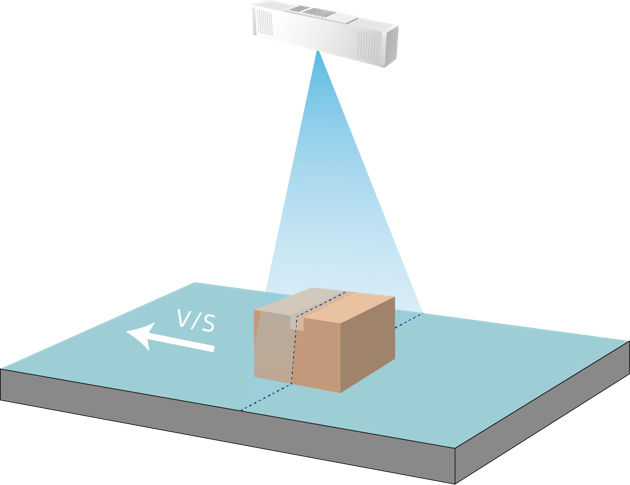

Illustration of Dynamic Linear 3D Camera Application Scenarios

The dynamic linear 3D camera is specifically designed for dynamic scenes, where the camera and objects need to have relative motion.

It is suitable for scenarios such as logistics parcel inspection, conveyor belt monitoring, and industrial production line quality control.

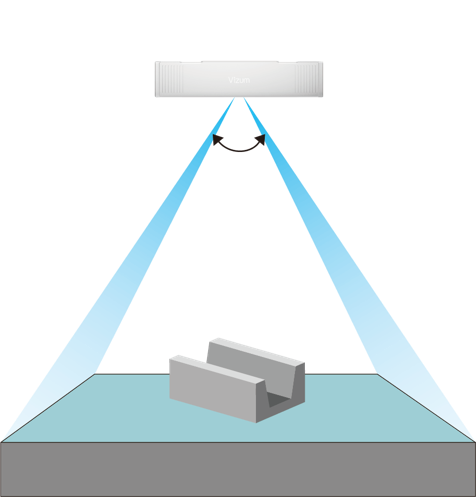

Illustration of Static Linear 3D Camera Application Scenarios

The static linear 3D camera is designed for static scenes, where both the camera and objects remain stationary.

It is suitable for scenarios such as robotic arm picking, robotic arm welding, and robotic arm grinding and cutting.

Industry Applications

With ViEye products, various application developments can be carried out, including 3D point cloud model reconstruction, 3D positioning, object counting, conveyor belt object flow monitoring, object dimension measurement, surface defect detection, and other secondary application developments.

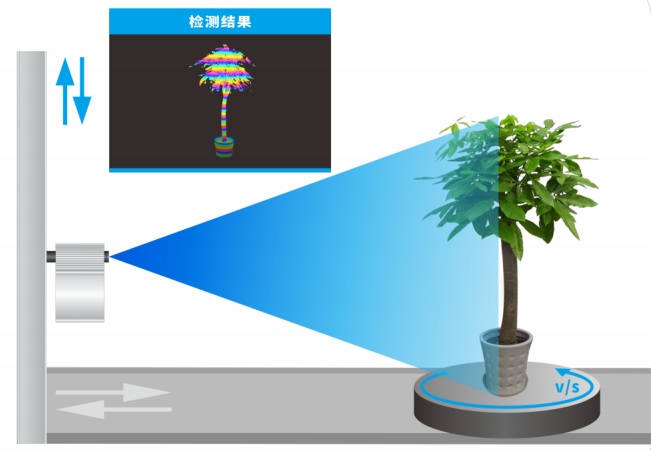

3D Point Cloud Model Reconstruction:

After relative motion between the object and the camera, a 3D point cloud model of the object’s surface can be output in real time.

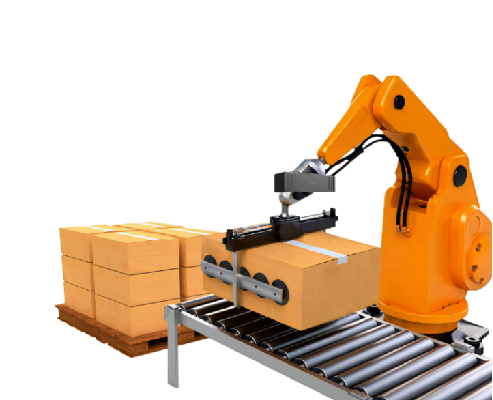

3D Positioning:

High-precision spatial coordinate and posture positioning can be performed on all point cloud data generated by the object. When combined with a robotic arm, it enables various industrial applications such as picking, loading and unloading, sorting, and welding control.

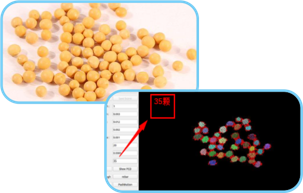

Object Counting:

Real-time segmentation and counting can be performed on objects that are placed individually or in contact with each other.

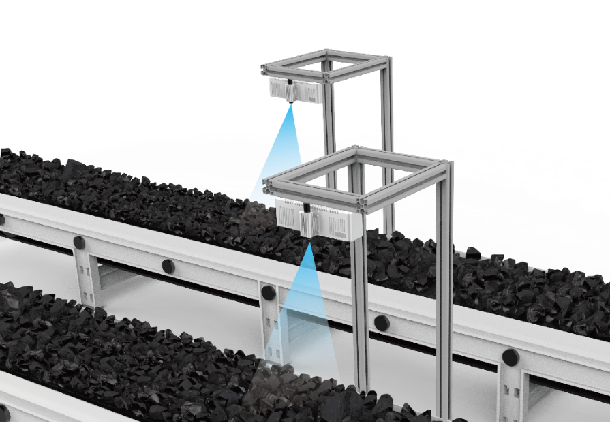

Conveyor Belt Object Flow Monitoring:

Real-time volume data calculation per unit of time can be performed on objects moving on the conveyor belt, enabling flow monitoring of the objects.

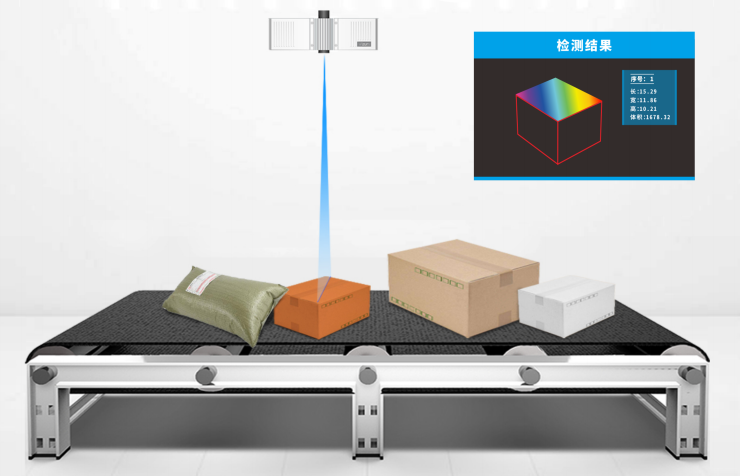

Object Dimension Measurement:

Capable of measuring the length, width, height, maximum volume, integral volume, groove depth, step height, and other dimensions of the object.

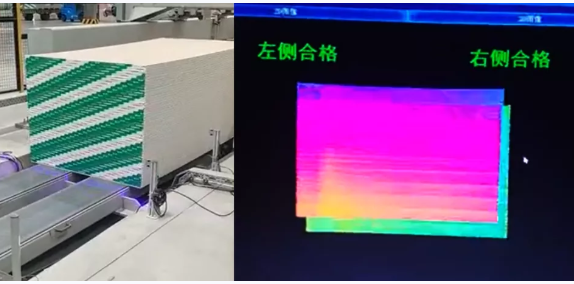

Surface Defect Detection:Capable of detecting surface defects such as flatness, angle, damage, dents, and protrusions on the object’s surface.