Specialized Camera for Welding

The ViEye is used in the industrial intelligent welding field and serves as the visual input for welding systems. Before welding, the ViEye, together with specialized software, can perform operations such as workpiece scanning, weld seam extraction, and weld seam planning. During welding, the ViEye can switch to a dynamic camera and perform weld seam tracking, achieving a dynamic and static integration. After the welding action is completed, the ViEye can serve as a detection tool and, together with the welding system, perform functions such as weld seam flatness inspection and dimensional deviation inspection.

Product Functions

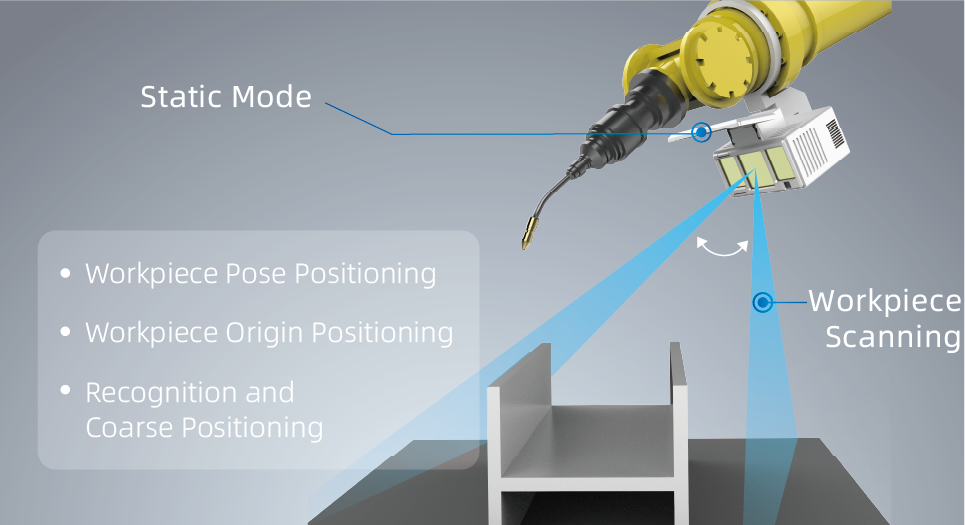

Workpiece Positioning

The welded workpiece is positioned as a whole, and the information of its attitude and position is provided, so that the welding origin can be located.

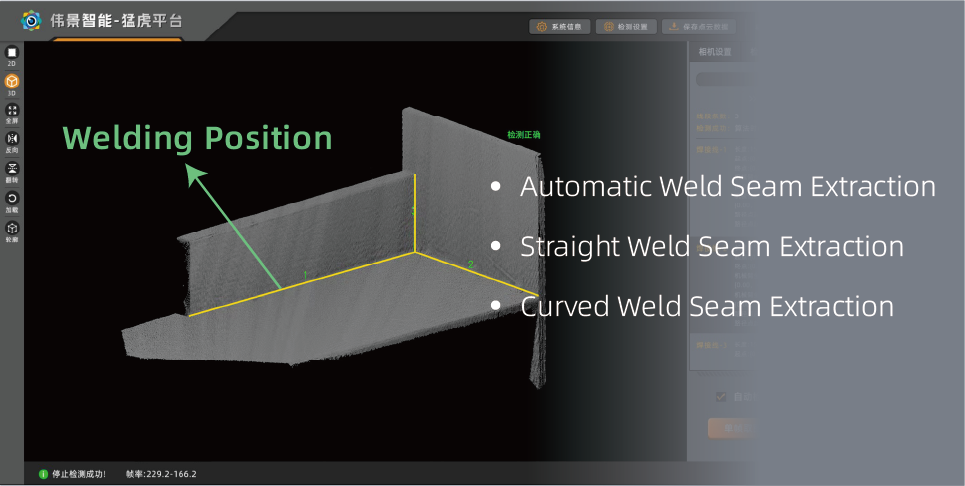

Weld Seam Extraction

Close-range fast scanning provides precise welding location, one-click generates welding path, and connects with welding robots.

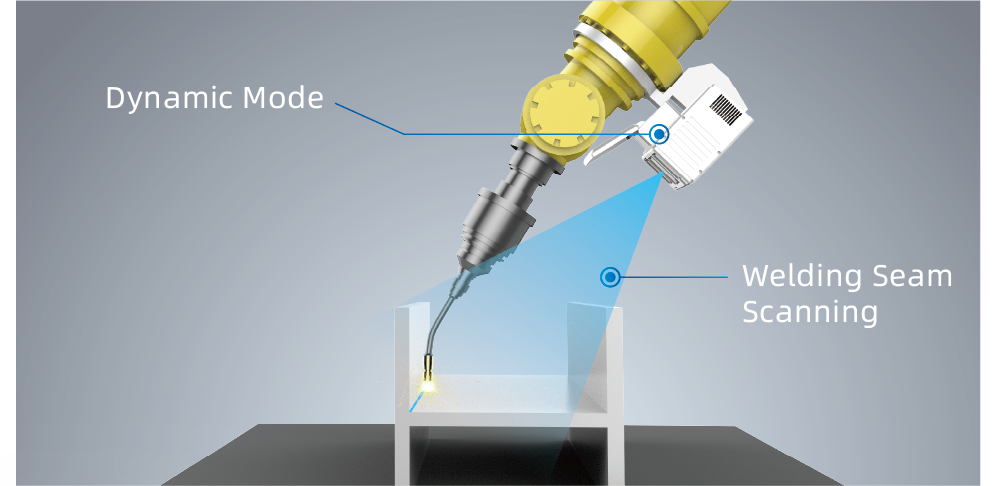

Weld Tracking

Real-time detection of welding seam position, correction of welding path,ensuring that the welding gun always follows the welding seam for welding, and guaranteeing welding quality.

Product Features

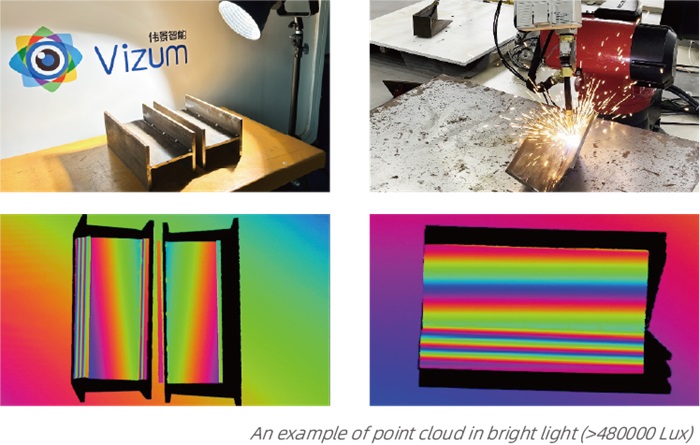

Resistant to strong light, anti-glare, and anti-absorption, adapting to various complex environments.

- Supports high-precision modeling in bright environments up to 480,000 Lux.

- Supporting object surface reflection and glossy material modeling without noise.

- Black light-absorbing material on object surface for flawless modeling

- Not afraid of welding arc light, high-precision scanning can still be performed during welding.

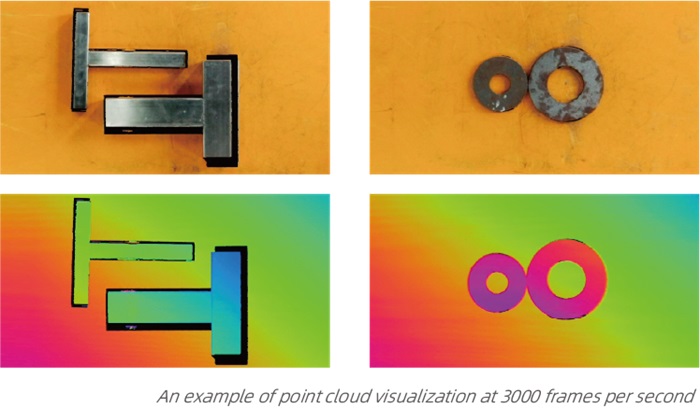

High precision and high frame rate to improve welding accuracy .

- Equipped with a high-resolution image chip, the number of single-line point clouds can reach up to 2048.

- Uses a global exposure chip, with a maximum line scanning rate of 3000 lines/s.

- High spatial positioning accuracy, meeting the refined scene detection requirements.

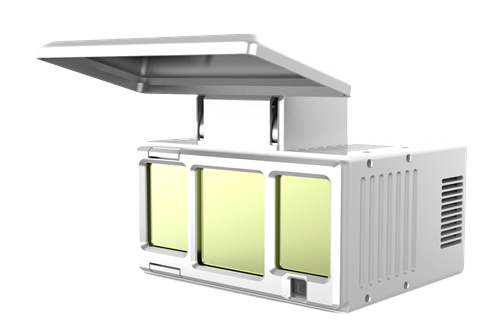

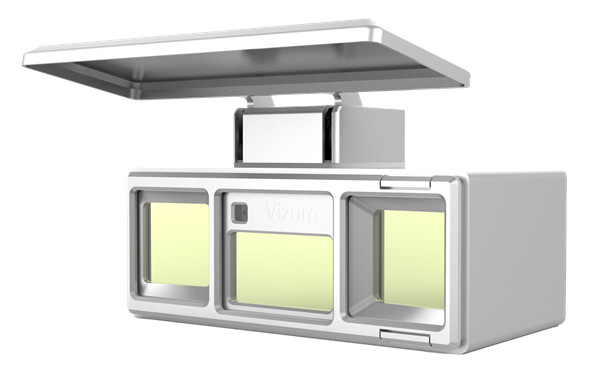

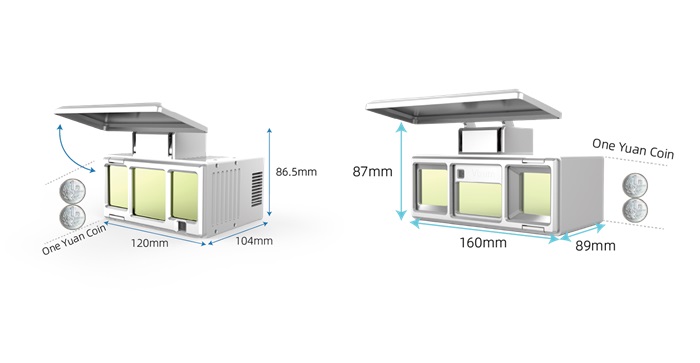

Light weight, compact, electric-driven anti-splash cover design.

- Weighing is suitable for lightweight robotic arm installation.

- Length suitable for welding scenarios in confined spaces.

- The electric-driven anti-splash cover design allows the cover to automatically close after scanning is completed.

- It can be controlled via software or an external trigger line, providing better lens protection and adapting to harsh environments.

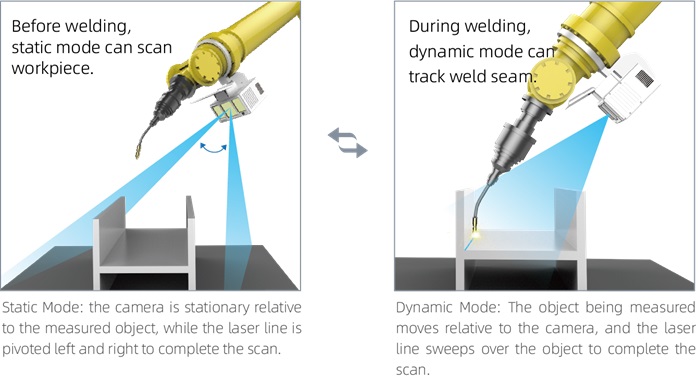

Dynamic and static integration, one camera for the entire welding process.

- Static mode supports workpiece scanning.

- Dynamic mode supports welding tracking.

- Dynamic and static in one, switching through software.

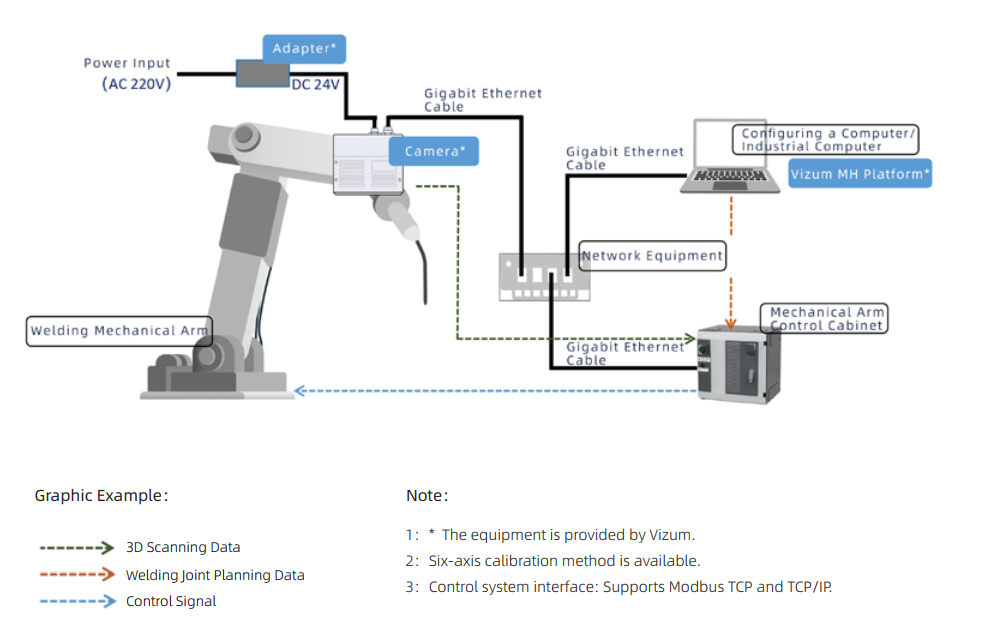

System Connection