Multi-Camera Array Fusion 3D Modeling System

System Overview

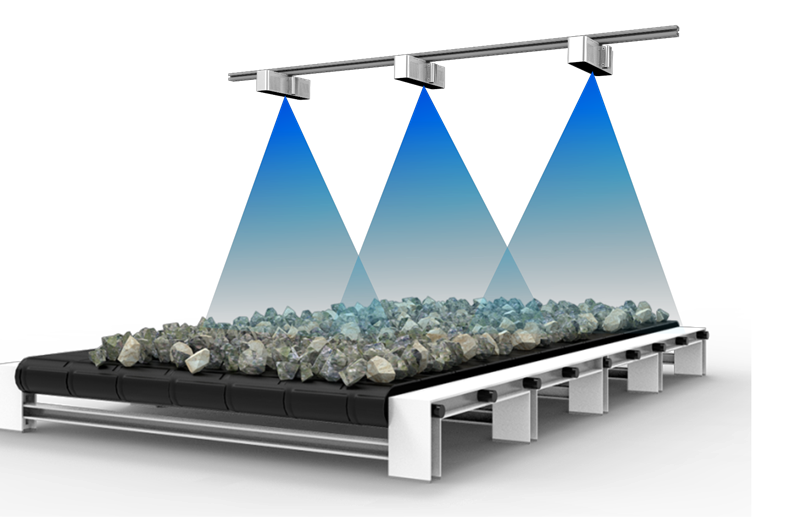

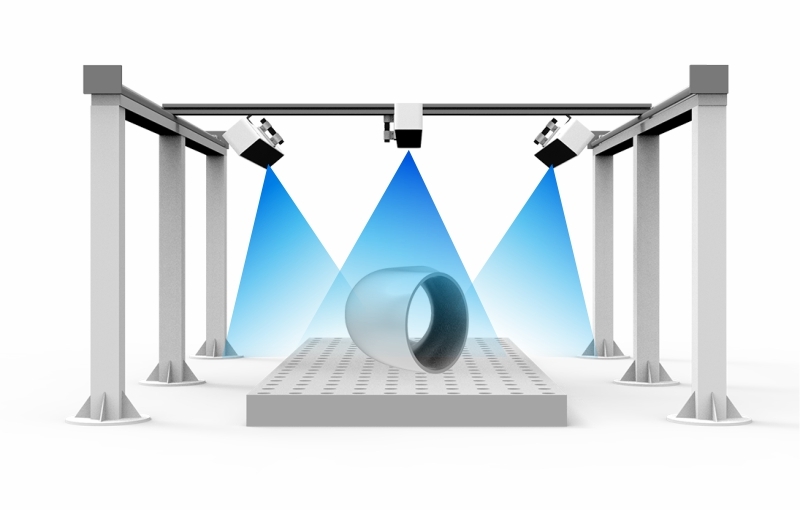

The Multi-Camera Array Fusion 3D Modeling System utilizes multiple line laser stereo cameras for implementation. Each stereo camera models a portion of the field of view, with overlapping areas between adjacent cameras. The point cloud data detected by each stereo camera is seamlessly fused and stitched using proprietary calibration and modeling algorithms, ultimately creating a complete 3D point cloud model of the object. This system is designed to meet the 3D modeling needs of large objects. Additionally, it supports various functional applications, including 3D positioning, defect detection, surface inspection, dimension measurement, and counting. The product features include intelligent terminal support, modularity, flexibility, wide field of view, high precision, adjustable installation height and angle, strong environmental adaptability, and broad versatility.

System Features

- Real-Time Point Cloud Data Fusion: Each camera is designed with an intelligent modular terminal, embedded with multiple processing chips. It can directly output point cloud depth data at the camera end, and real-time data fusion is performed through the industrial control computer.

- Ultra-Wide Field of View Scanning: A single stereo camera can achieve a 3m field of view with millimeter-level accuracy. By adding multiple cameras, the field of view can be expanded to cover a larger range.

- High Precision: For large objects and wide field of view scenarios, the fusion accuracy can reach up to ±0.2mm.

- One-Click Calibration: After installing multiple cameras, the system allows for one-click calibration of each camera’s initial position and coordinate system using calibration tools.

- High Flexibility: The field of view, installation distance, and other parameters can be configured based on scene requirements. Multiple cameras can be combined to expand the field of view while maintaining precision.

- Strong Environmental Adaptability: The system can function properly in both indoor and outdoor environments, even under low light conditions.

- Adaptability to Various Complex Object Scenarios: It supports 3D modeling of large moving and stationary objects and can adjust the camera scanning angle in real time to meet the detection needs of different object postures.

- Wide Applicability: Suitable for a variety of large-scale inspection scenarios, including roadways, large castings, large logistics operations, and large workpieces for 3D modeling.

- Supports Multiple Trigger Methods: The system supports software trigger, level trigger, pulse trigger, and other methods, making it easy for users to integrate into existing systems and develop applications.

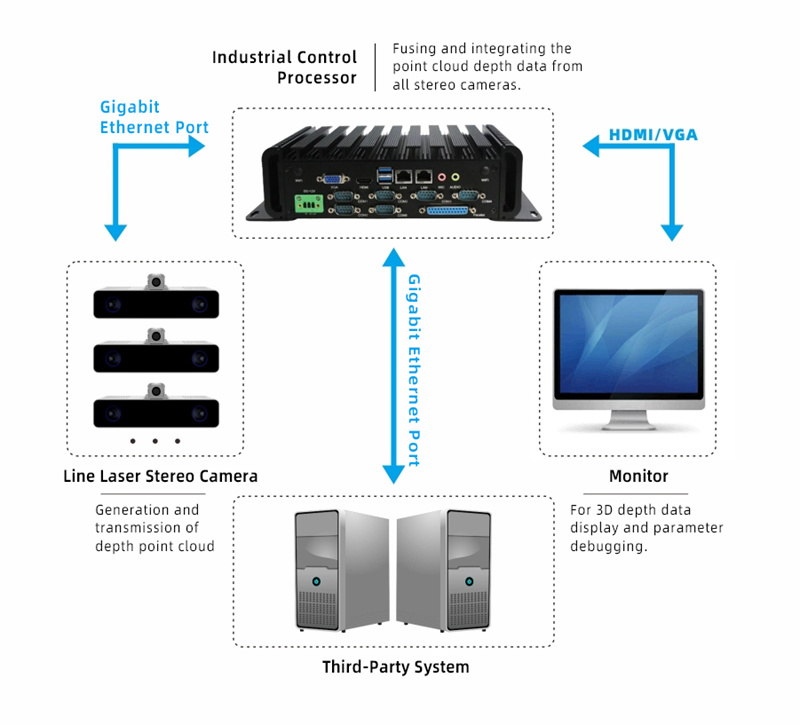

System Communication Diagram

The line laser stereo camera features intelligent terminal capabilities. After multiple stereo cameras generate point cloud depth data, it can be transmitted to the central control processor via a Gigabit Ethernet interface for data fusion. On the central control processor, the embedded application interface software allows for the 3D display of point cloud depth data and camera parameter adjustments on the monitor. The fused data results can also be transmitted to third-party systems via the Gigabit Ethernet interface.

System Applications

By using a multi-camera array fusion 3D modeling system, various scene modeling applications with large depth of field and wide field of view can be developed, including the measurement of large items in logistics transportation, the detection of road surface flatness and defects, the surface inspection of automobiles, the size measurement and surface inspection of large castings, and many other scene application developments.