As a key sector closely tied to daily life, the logistics industry plays a vital role in supporting public services and consumer needs.

With the rise of online shopping as a national habit, the volume of express deliveries has grown explosively. In 2019 alone, China’s total online retail sales reached a new record of RMB 10.6324 trillion, with express parcel volume exceeding 63 billion pieces. Faced with such massive volumes, improving logistics efficiency and processing speed has become more urgent than ever.

Building smart logistics powered by automation and intelligent technologies is widely recognized as an effective solution to enhance efficiency. Recently, China’s State Post Bureau and Ministry of Industry and Information Technology jointly issued the Opinions on Promoting the Deep Integration of the Courier and Manufacturing Industries, which calls for the development of smart logistics systems. The directive encourages manufacturing and logistics companies to co-develop smart warehouses, intelligent logistics robots, automated sorting and packaging equipment, autonomous vehicles, and cold chain delivery technologies, accelerating the modernization of logistics infrastructure.

With strong policy support and clear market demand, the push for intelligent logistics transformation is gaining momentum. However, despite increasing participation in the development of smart logistics equipment, truly viable and widely applicable solutions remain scarce, and many challenges still stand in the way of large-scale adoption.

Challenges in Intelligent Logistics

In modern logistics operations, high-speed volume measurement, package counting, and parcel sorting are routine tasks. As parcel volumes continue to rise rapidly, manual operations are increasingly showing their limitations—low efficiency, high labor intensity, and a high risk of human error. Moreover, these manual processes cannot be easily integrated with ERP or WMS management systems, failing to meet the requirements of digital logistics. This has prompted many companies to seek intelligent equipment to replace manual labor.

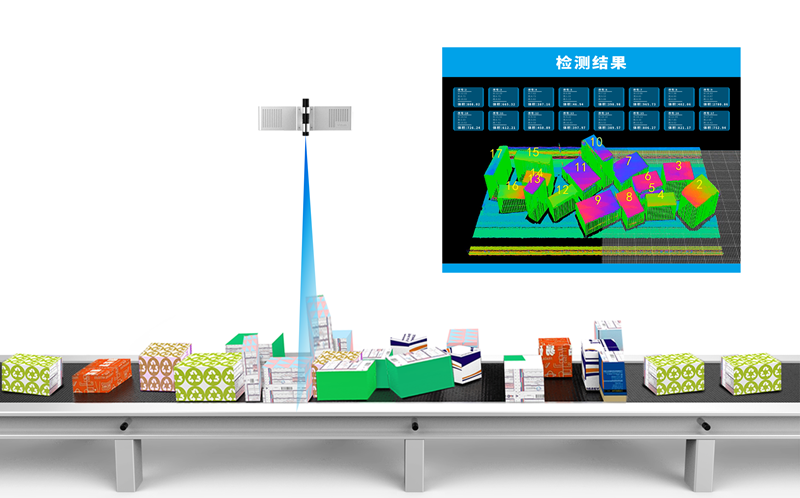

At sorting centers, hundreds or even thousands of parcels are densely stacked and continuously fed through conveyor systems. One of the most critical challenges is the accurate and fast segmentation of each individual package. The diverse sizes, shapes, and packaging types further complicate this task. Current market solutions still struggle to precisely differentiate each parcel in real-world conditions. Issues such as limited field of view, inability to handle multiple sizes simultaneously, and vulnerability to environmental interference prevent these solutions from fully supporting intelligent logistics applications.

Vizum Breaks Through with Smart Logistics Innovation

In response to the practical challenges faced by its clients, Vizum has developed the Smart Logistics 3.0 System, integrating cutting-edge image processing, stereo vision technology, and its proprietary Natural Learning® algorithm.

This next-generation system enables intelligent, three-dimensional perception and rapid adaptive learning. It delivers robust functions including real-time measurement of package dimensions (length, width, height), integrated volume calculation, object segmentation, object counting, orientation detection, and precise localization of package centers and corners—even under high-speed conveyor conditions. These capabilities support a wide range of logistics needs, from data management and inventory counting to automated sorting.

The Smart Logistics 3.0 System is designed for real-world deployment and has demonstrated outstanding performance across complex logistics environments:

- Accurately segments adjacent and touching parcels of various types, with a segmentation accuracy of over 99.9%;

- Supports detection of fast-moving parcels up to 4 m/s with millimeter-level precision, capable of inspecting up to 15,000 packages per hour;

- Resolves issues in detecting reflective surfaces such as bright-colored packaging and tape;

- Handles low-reflectivity materials including black and dark-colored parcels;

- Maintains high accuracy when detecting parcels of mixed colors and contrasts;

- Supports detection across multiple packaging materials—cardboard boxes, woven bags, wooden crates, and metal containers;

- Simultaneously detects parcels of different shapes and sizes, including standard cartons, soft bags, and irregular shapes;

- Operates reliably in environments with strong ambient lighting or low-light conditions, requiring no additional lighting support;

- Features one-click horizontal calibration, addressing conveyor belt tilt, uneven surfaces, and vibration;

- Supports both indoor and outdoor logistics scenarios, including warehouses and open-air docks;

- Meets industrial-grade standards, ensuring operation under extreme temperatures, electromagnetic environments, and dusty or wet conditions.

Empowering Smart Logistics and Elevating the Industry

High Precision

Backed by Vizum’s proprietary stereo vision camera, the Smart Logistics 3.0 System delivers exceptional measurement accuracy. For example, at an installation height of 2 meters, it can measure parcels sized 1m × 1m × 1m with an error of less than 1mm—well above industry norms.

Large Depth of Field and Wide Field of View

Without needing system adjustments, the 3.0 System can detect parcels ranging from a few centimeters to several meters in size, while maintaining millimeter-level accuracy. It supports package detection of up to 3 meters in a single view.

High Flexibility

The system is highly configurable, with adjustable lens parameters, interocular distance, and working range, allowing it to meet different application needs. It also supports multi-camera stitching for ultra-large object detection, enabling logistics inspection for rail or sea freight scenarios.

No External Trigger Required

The system operates in self-triggering mode, eliminating the need for additional sensors and reducing integration and retrofit costs for users.

No Site Modifications Needed

Designed with enterprise adoption in mind, the 3.0 System can be deployed directly without requiring changes to existing infrastructure—minimizing installation costs and shortening deployment cycles.

Multiple Trigger Modes Supported

It supports software triggers, as well as high/low voltage triggers, for seamless synchronization with third-party systems.

Precise Object Localization

The system enables accurate identification and localization of object centers and corners, and can be integrated with robotic arms for downstream sorting and handling tasks.

In an era of rising labor costs and the ongoing shift toward intelligent transformation, reducing cost and improving efficiency are essential goals for the future of logistics. Intelligent logistics is no longer a vision—it is an inevitable step in the industry’s evolution.

Vizum specializes in smart vision technology with a strong technical team and extensive industry experience. In logistics alone, the company holds more than ten patents, and its independently developed Smart Logistics 3.0 System has achieved internationally advanced performance benchmarks. The system significantly enhances the intelligent perception and recognition capabilities of logistics operations, delivering practical, scalable solutions for real-world deployment across diverse logistics environments.