As a pillar of the national economy, China’s steel industry has long drawn widespread attention. Since the release of the “2019 Key Points for Reducing Excess Steel Capacity” policy, the industry has entered a new phase. In the post-pandemic era, steel enterprises face a pressing question: how to seize this moment and steer towards high-quality development?

In steel production, bars are delivered in bundles, each requiring tags or labels that specify grade, heat number, specification, and length—essentially the “ID card” of the product. These markings reflect the quality level of the bars and help enhance product value, making them a priority for many steel manufacturers.

The labeling process, often referred to as rebar marking, is still predominantly manual, involving position identification and welding of tags. However, the accelerating production pace makes manual operations increasingly unsustainable. High-intensity, repetitive tasks easily lead to fatigue and mistakes, while the harsh environment—characterized by dust and noise—further threatens worker health. These challenges have become bottlenecks for enterprise growth. Automation and intelligent transformation offer a promising solution.

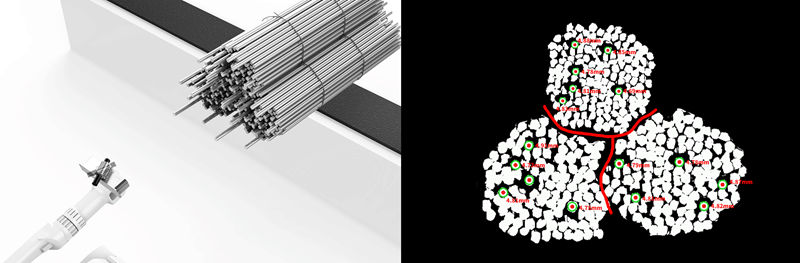

Rebar tags are typically affixed to the outermost rods for visibility and ease of operation. Accurately identifying the outer bars is thus critical to automation.

Most AI companies rely on 2D image-based deep learning, which demands extensive datasets to train models. Yet in real-world conditions, rebar bundles present non-uniform surfaces, varying cross-sectional shapes, corrosion levels, and a wide range of sizes. It is nearly impossible to train a model that encompasses all possible scenarios, making traditional deep learning methods inadequate for automated marking in steel applications.

Vizum Bridges AI and Smart Steel Manufacturing

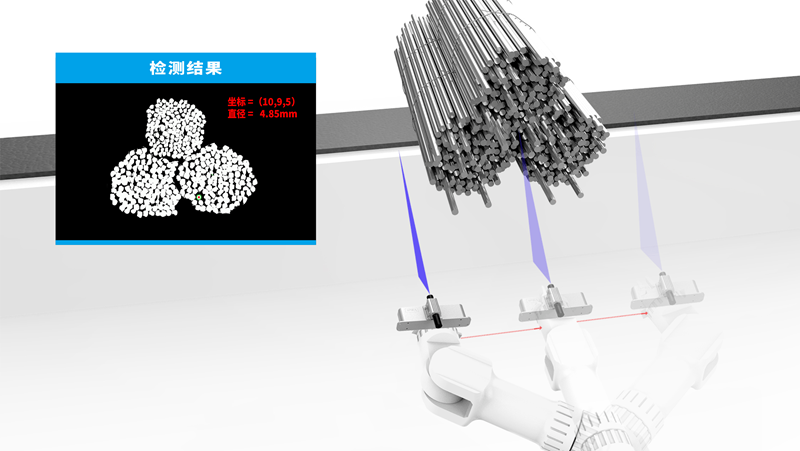

Amid the industry’s push for intelligent upgrades, Vizum has developed an innovative solution grounded in real-world needs. By integrating stereo vision technology with its proprietary “Natural Learning®” algorithm, the company has launched an automated bar marking system. This system eliminates the need for intensive manual labor, delivering fast, accurate, and stable marking operations. It helps steel enterprises accelerate their intelligent transformation and significantly improve operational efficiency and product quality.

Designed for automatic bar marking in steel processing environments, the system accurately locates the marking position on bar bundles and seamlessly integrates with existing automatic label printers and tag welding machines for a fully automated process.

By scanning and acquiring 3D cross-sectional data of bundled or stacked bars, the AI algorithm determines the center coordinates and diameters of the outermost bars. It also distinguishes between different bundles, enabling the system to guide marking devices to complete the operation autonomously.

Automated Bar Marking System Designed for Real-World Steel Industry Applications

Vizum’s system offers two operational modes tailored to different industrial needs. For bundles with uneven cross-sections and large fields of view, a robotic arm ensures precision without visual obstructions. For compact setups where simplicity is key, a fixed installation model is available, offering easy deployment and fast system response.

Even in complex environments—disordered placement, varying lengths, reflective surfaces, rusted textures—the system maintains a high positioning accuracy of up to 0.3 mm. Thanks to its Natural Learning® algorithm, no retraining is required for different bar specifications or bundle sizes. Adjusting the camera’s height and working distance according to the field of view is sufficient for immediate use.

The system is also designed for easy installation and operation: one-click startup brings it online instantly. It supports workflows such as warehouse in/out tracking and production management, reducing human intervention while increasing accuracy and efficiency.

To accommodate evolving client needs and rapid upgrade cycles, the system supports cloud-based updates. With a single click, the user can upgrade to the latest version—simple and convenient.

Vizum offers flexible collaboration models tailored to users’ technical capacities. For clients lacking visual development expertise, the company provides complete turnkey vision solutions that can be directly integrated with third-party systems. For more advanced users requiring customized integration, Vizum supplies a binocular laser-based development platform along with technical support to assist in completing their own vision systems.

Vizum’s automated bar marking system tackles the challenges of repetitive labor and low efficiency head-on. It is a practical, production-ready solution that directly addresses the pain points of the steel industry, reducing labor costs and improving accuracy.

As China continues to cement its status as the world’s largest steel producer and the second-largest economy, enterprise competitiveness increasingly hinges on mastery of advanced technologies. Vizum is committed to leveraging its strengths to deliver mature, productized solutions that open new growth opportunities and drive the steel industry forward.