Manufacturing has long been a cornerstone of China’s economy, playing a critical role in national development. However, rising labor costs and a shrinking workforce have created growing challenges for manufacturers, including labor shortages and increased operational expenses. In response, smart manufacturing—driven by technologies like robotics and machine vision—has become a key strategic direction for the future of the industry. By replacing manual labor with automation, smart manufacturing improves production speed, enhances quality, and helps companies reduce costs and increase efficiency. As a result, it is receiving increasing attention across the industrial sector.

Stereo vision provides machines with visual perception, making it an essential component of smart manufacturing. It is widely used in various applications—from automated part picking in workshops to package volume measurement in logistics. For example, vision cameras help identify parts for robotic arms to grasp, or measure the dimensions of parcels for sorting and shipping.

As smart transformation deepens, the demand for machine vision applications has surged. At the same time, stereo vision technology faces new challenges, including high-speed object detection, long-range and wide-area measurement, and the need for robust environmental adaptability. The market is in urgent need of a solution that can break through these technical barriers and unlock broader application potential.

Addressing Pain Points with Breakthrough Innovation

Vizum has been dedicated to the development of stereo vision technologies since its founding. With a deep understanding of industry pain points and rich product experience, the company has officially launched its new flagship product line: the Intelligent Terminal Stereo Vision Camera—ViEye.

ViEye: Designed to Solve Real-World Challenges

Built on the principle of binocular stereo vision, the ViEye camera delivers powerful capabilities such as 3D modeling, flow volume analysis, spatial positioning, dimension measurement, and high-speed object detection. With features including wide field of view, high-speed processing, and intelligent on-device computing, it directly addresses many of the industry’s most pressing needs.

To accelerate deployment and simplify integration, ViEye features edge processing: point cloud data acquisition and computation are handled directly on the device. Users can obtain immediate results without the need for costly external processing units. The system also integrates easily with PLCs and other control systems, making it simple to adopt and operate.

Outstanding Performance and Flexibility

ViEye delivers exceptional detection performance, even at speeds up to 4 m/s with millimeter-level precision—making it ideal for high-speed scenarios such as tobacco inspection or logistics parcel tracking. It also supports variable-speed applications, significantly boosting productivity.

In large-scale inspection scenarios—such as measuring castings or industrial components—the camera offers a deep field of view and wide coverage. Depending on installation distance and accuracy requirements, a single camera can cover up to 5 meters, and multi-camera stitching supports even greater distances and ultra-wide area detection.

The system performs reliably in challenging environments, including outdoor bright light, dim indoor settings, high humidity, dust, and extreme temperatures. Its rugged design ensures high adaptability and robustness in real-world industrial conditions.

ViEye also supports modular customization. Users can select lenses, adjust the baseline, and configure the camera according to installation distance, detection range, and precision requirements—offering maximum flexibility for diverse application needs.

Next-Generation RGBD Camera Coming Soon

In some applications—such as package sorting or robotic picking—color information is just as important as shape and size. However, traditional 3D cameras lack the ability to capture color, often forcing users to deploy separate color cameras, increasing both complexity and cost.

Vizum will soon release a new version of ViEye with full RGBD capabilities. With just one device, users can obtain 3D point cloud models, depth maps, grayscale images, and full-color visuals. This enables a wide range of functions including QR code recognition, stereo localization, defect detection, dimension measurement, and color-based classification—all from a single camera. This powerful all-in-one solution helps customers reduce system costs while enhancing functionality and efficiency.

Wide Range of Real-World Applications

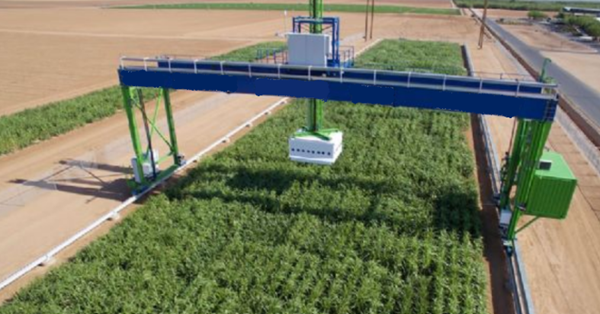

Smart Agriculture: Field phenotyping, grain counting, crop sorting

Smart Mining: Coal sorting, coal flow monitoring, volume weighing

Smart Logistics: Volume measurement, parcel sorting, object segmentation

Smart Manufacturing: Automated loading/unloading, palletizing/de-palletizing, compliance inspection

Steel Industry: Rod counting, weld mark detection

Rail Transit: Pantograph-catenary detection, intrusion detection, rail inspection

The ViEye terminal stereo camera is the result of Vizum’s deep expertise and innovation in the field of stereo vision. With industry-leading performance and user-centric design, it offers a powerful new solution for overcoming key challenges in 3D vision applications. By expanding the capabilities and accessibility of stereo vision, Vizum is accelerating the intelligent and automated transformation of Chinese industry.