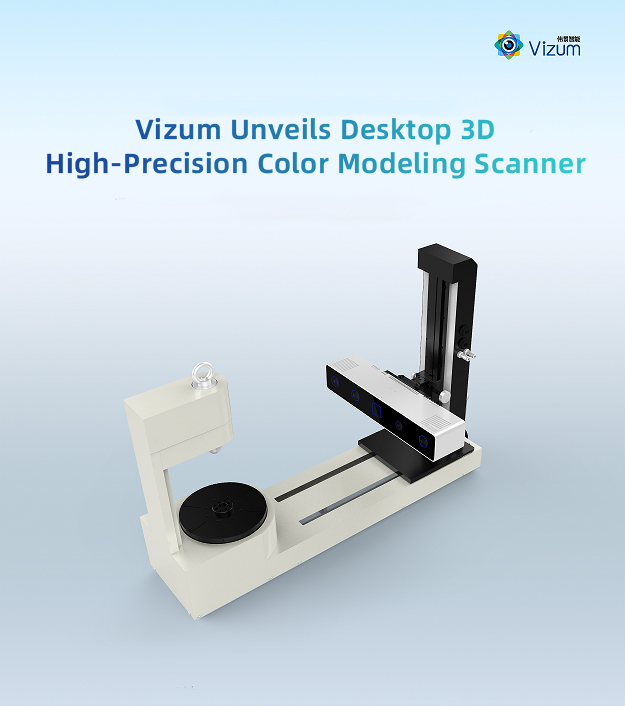

Vizum has officially released its latest product—the Desktop 3D High-Precision Color Modeling Scanner. This lightweight, high-precision scanner has been independently developed to meet the increasing demand for real-time modeling in the industrial sector. Designed specifically for the 3D scanning and real-time modeling of various micro industrial parts, the device requires no target markers and delivers instant results, offering a new approach to object scanning and modeling.

Key Advantages

01 Real-time output of color 3D data with precision up to ±0.2mm

The desktop scanner is capable of real-time scanning and outputting color modeling data for a wide range of micro industrial components. Tests have shown that within a working range of 120–420mm, the system achieves a precision of up to ±0.2mm.

02 High-performance chip integration with fusion accuracy <0.01mm

Featuring an intelligent, modular terminal design, the device is embedded with a high-performance processing chip. Camera fusion accuracy is less than 0.01mm.

03 Adjustable track design for 120–420mm scanning distance

The adjustable track structure allows the user to adapt the field of view based on object size, supporting a scanning range from 120mm to 420mm.

04 360-degree rotating platform with max scanning width of 360mm @ 450mm

Equipped with a 360-degree rotating platform, the scanner enables full-angle scanning. At a scanning distance of 450mm, it supports a maximum scan width of 360mm.

05 Laser-based scanning with full-process light interference resistance

Using infrared laser technology, the system performs real-time modeling under any lighting condition, unaffected by ambient light.

06 Lightweight industrial-grade design for flexible deployment

With a compact, high-integration structure, the device weighs just 25kg, making it adaptable to a variety of work environments.

Application Scenarios