As the intelligent era accelerates, technologies once considered niche are rapidly becoming mainstream. Among them, 3D modeling has emerged as a critical pillar of smart technology, drawing increasing attention. Alongside this interest, market expectations for 3D scanning systems—particularly in terms of accuracy, speed, and adaptability—are rising sharply.

One persistent challenge in the field is the real-time acquisition of high-precision 3D point cloud data for large objects. Vizum has addressed this issue head-on with the independent development and launch of its Full-Scale 3D Modeling System for Large Objects—a breakthrough device designed to reconstruct the full spatial geometry of large-scale items with remarkable precision and speed.

This new system represents a significant advance in intelligent 3D modeling equipment, capable of restoring a large object’s three-dimensional structure with high accuracy.

At present, large-object 3D scanning globally is dominated by two mainstream solutions: structured light systems and multi-camera array setups. Leading international providers include ARTEC (USA) and Anthroscan (Germany). However, these approaches have inherent drawbacks—such as time-consuming data fusion processes, high costs, and limited support for small-to-medium-sized objects. Structured light systems, for instance, cannot capture complete point cloud data in a single pass, requiring post-processing to stitch multiple scans together. Multi-camera arrays involve numerous high-resolution sensors, making them prohibitively expensive for many applications. These limitations have slowed widespread adoption. In China, the market has long relied on imported solutions, lacking competitive domestic alternatives with technological advantages. The launch of Vizum’s full-scale 3D modeling system is poised to break that monopoly, introducing a viable Chinese alternative to high-end imported equipment.

In real-world applications, conventional 3D modeling technologies typically support objects no taller or wider than 0.5 meters, with working distances capped at around 0.3 meters. This makes them unsuitable for large or distant targets. In contrast, Vizum’s new system supports scanning ranges of 2 meters and beyond (with adjustable working distance), and can model objects up to 2 meters tall—with options for larger custom sizes. The system delivers positioning accuracy from 0.05 mm to 1 mm, depending on configuration.

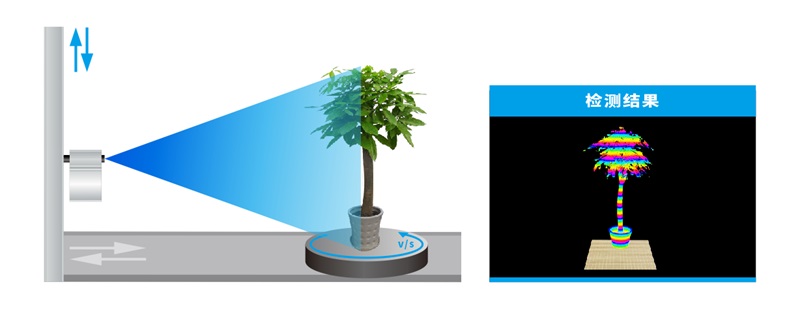

While most existing systems use handheld scanners for large object modeling, their small detection ranges necessitate multiple passes from different angles, followed by extensive data stitching and fusion—often taking up to 8 minutes per object. The process is time-consuming and labor-intensive. Vizum’s system fundamentally changes this workflow. It captures and fuses 3D data in real time, delivering a fully reconstructed high-precision 360° point cloud model immediately after one complete rotation. There is no need for post-scan data fusion. The current rotation cycle takes just 30 seconds, and the speed can be adjusted based on the requirements of different applications. The system also supports direct output to 3D printers for physical model production.