3D vision is a fundamental component of machine vision and a key branch of artificial intelligence.

This technology offers a comprehensive and accurate representation of object information and holds immense potential for development. It is widely used across industries, from micro-scale tasks like semiconductor inspection to large-scale applications such as automotive manufacturing and wood surface analysis.

As industry demands grow and the use of 3D technology expands, 3D inspection systems are also encountering new challenges. One of the most pressing is achieving both wide field of view and high precision in a single solution.

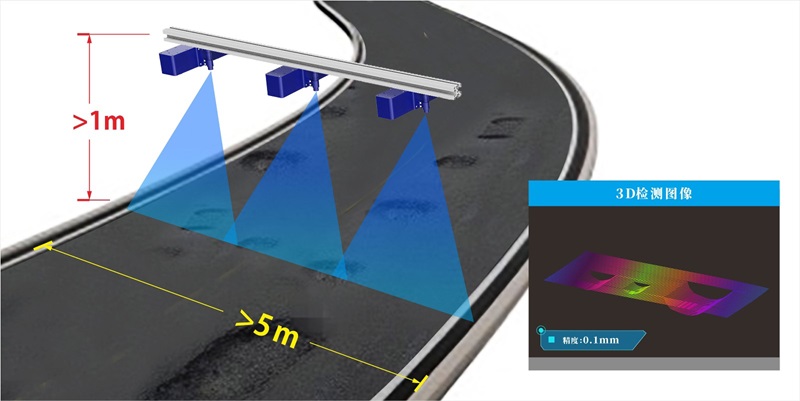

In large-scale scenarios such as highway surface inspection, traditional systems often face a dilemma: at an optimal working distance that ensures adequate precision, the field of view may be too narrow to cover a full lane. Extending the working distance compromises precision and fails to meet inspection standards. Moreover, the market offers few products that balance both field coverage and accuracy.

This challenge has pushed beyond the capabilities of single 3D cameras. In response, Vizum has developed the Multi-Camera Array Fusion 3D Modeling System, which integrates multiple ViEye units to capture and combine overlapping fields of view. With synchronized operation, the system merges data seamlessly, expanding the inspection range while maintaining precision and effectively resolving the conflict between wide field of view and high resolution.

Operating Principle of the Multi-Camera Array Fusion 3D Modeling System

The system coordinates multiple ViEye cameras, each capturing a portion of the object. Their fields of view are carefully aligned, and Vizum’s proprietary algorithm fuses the scanning data into a seamless, continuous 3D representation. The result is a complete and accurate 3D model of the object.

Advantages of the Multi-Camera Array Fusion 3D Modeling System

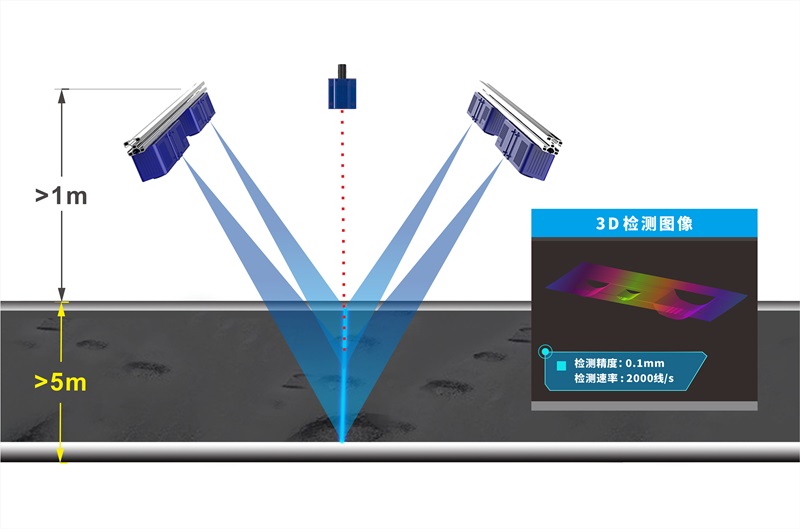

- The system offers a wide field of view without compromising on precision. It is configurable according to customer requirements, including view range, resolution, and working distance. For example, at a working distance of one meter, the system achieves a detection precision of 0.1 mm. By combining multiple cameras, the field of view can be extended beyond five meters, making the system ideal for applications such as contour inspection of large cast components, wood grain analysis for furniture manufacturing, and road surface defect detection.

- The system delivers high-speed depth data processing. Processing speed reaches up to 1,000 lines per second. Since the cameras use line laser scanning and the overlapping areas are minimal, adding more cameras does not slow down processing. Even in large-scale, multi-camera setups, the system maintains fast, efficient data handling.

- Depth data is generated and displayed in real time. Vizum’s proprietary algorithms enable seamless data stitching across multiple cameras, allowing for instant formation and visualization of 3D depth information. This real-time capability directly enhances processing speed and increases productivity for users.

- Installation is highly flexible. The ViEye-based system allows separate installation of stereo cameras and auxiliary laser modules, making it adaptable to various environments. Users can further boost scanning speeds by optimizing camera array layouts. For example, a dual-row configuration spanning five meters can achieve a scanning rate of 2,000 lines per second, significantly expanding the range of potential applications.

Application Scenarios for the Multi-Camera Array Fusion 3D Modeling System

Market Impact of the Multi-Camera Array Fusion 3D Modeling System

- The system brings 3D inspection into wide-field applications while maintaining high resolution.

- It ensures fast data processing for efficient system operation.

- Real-time data generation and display boost production efficiency and give customers a competitive edge.