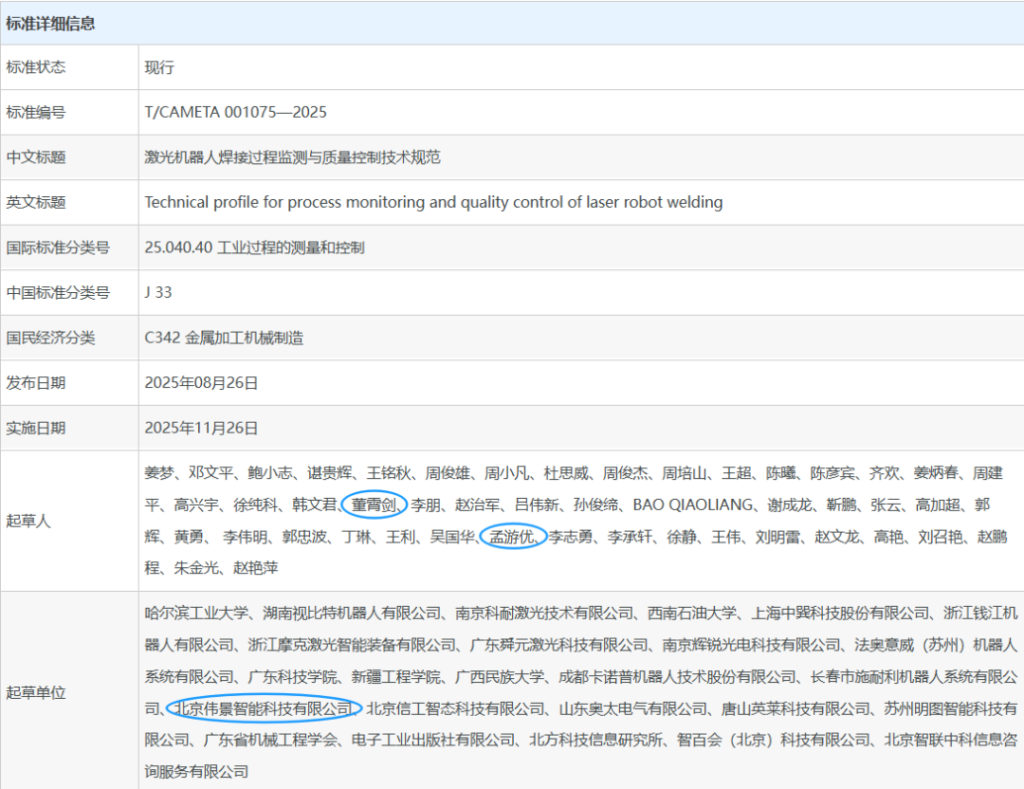

On August 26, the “Technical Specification for Process Monitoring and Quality Control of Laser Robotic Welding,” led by the China Association for Mechatronics Technology Applications, was officially released. This comprehensive standard focuses on process monitoring and quality control for laser welding, covering the entire chain from parameter acquisition and process monitoring to quality evaluation and defect determination. It effectively addresses the long-standing absence of unified technical specifications in the industry.

Standardization · A Milestone for the Industry

As a core process in next-generation intelligent manufacturing, laser welding is widely applied across high-end sectors such as automotive body manufacturing, battery modules, rail transit, and aerospace. However, challenges such as deep-penetration welds, strong light reflection, and welding spatter have made defect detection and quality control persistent bottlenecks. The release of this specification not only provides companies with a unified reference for process design, equipment selection, and quality evaluation but also promotes the development of a more efficient and transparent quality control system across the value chain, enhancing the global competitiveness of China’s laser welding technology.

Independent Vision · Vizum’s Contribution

As one of the key contributors, Vizum played a vital role in providing both technical input and validation support for the standard. Leveraging its expertise in 3D vision, Vizum introduced its proprietary “line-laser + binocular stereo vision” dual-architecture, which enables stable imaging even under 480,000 Lux of strong light interference and generates real-time high-precision point cloud data. This significantly improves weld imaging accuracy and defect recognition. The technology has become an important reference within the specification, laying a solid foundation for the establishment of unified industry standards.

Proven Strength · Recognized Excellence

As a National High-Tech Enterprise and a Beijing “Specialized and Innovative” SME, Vizum has consistently focused on the independent development and industrialization of industrial cameras and humanoid robots, building an integrated technology system that spans algorithms, core software, and hardware platforms. Backed by more than 170 core patents, Vizum’s industrial-grade line-laser 3D cameras have achieved international certifications including CE, ISO9001, and FCC, demonstrating globally recognized technological strength. To date, Vizum has delivered over 5,000 projects and served more than 1,000 clients, with applications spanning industrial automation, intelligent welding, robotic grasping, smart mining, steel metallurgy, railway, and agriculture—continuously enabling the intelligent transformation of diverse industries.

Looking Ahead · Driving Intelligent Manufacturing Together

Vizum’s participation in the formulation of this national-level industry standard not only underscores its leadership in intelligent welding vision technology but also reflects its commitment to advancing industry-wide standardization. Moving forward, Vizum will continue to drive innovation through its core technologies, deepen the integration of 3D vision and intelligent welding, accelerate the industrialization of research outcomes, and contribute to the intelligent upgrading of welding processes and the high-quality development of manufacturing.