As industrial automation continues to advance rapidly, welding technologies are evolving as well. Accurate positioning and seam tracking are critical to ensuring welding quality. To meet these demands, Vizum has developed the ViEye Smart Welding Camera—a high-performance, laser line 3D industrial camera designed specifically for intelligent welding applications. This camera introduces an innovative solution for intelligent industrial welding.

The ViEye stands out with features such as high precision, strong light resistance, compact size, splash-proof shielding, and integration of dynamic and static modes—all of which make it a powerful tool for smart welding. It supports workpiece positioning, weld seam extraction, and real-time weld seam tracking. Paired with Vizum’s proprietary software, users can easily scan workpieces and plan welding paths. During the welding process, the ViEye can be switched to dynamic mode to continuously track the seam, ensuring the welding torch precisely follows the seam to enhance welding quality. After welding, the camera can also be used as an inspection tool to check weld flatness and dimensional deviations in coordination with the welding system.

Key Functions

Workpiece Positioning

Provides complete positioning of the welding workpiece, including posture and coordinates, and identifies the welding starting point.

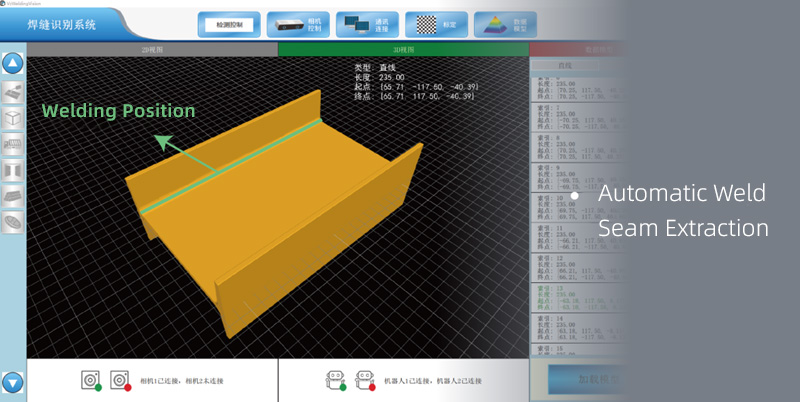

Weld Seam Extraction

Enables fast close-range scanning and accurate weld seam localization, generating welding paths with one click for robotic welding integration.

Weld Seam Tracking

Tracks the weld seam in real time and adjusts the welding path to ensure the torch continuously follows the seam, guaranteeing welding accuracy.

Product Highlights

Resistant to Strong Light, Reflections, and Absorptive Materials

Operates reliably under intense lighting up to 180,000 lux, accurately scans reflective and polished surfaces without noise, and handles black absorptive materials without missing data.

High Precision & Frame Rate for Improved Welding Accuracy

Equipped with a high-resolution image sensor, vertical resolution up to 2048 pixels, global shutter, and line scan frame rate up to 3000 FPS. Spatial positioning precision reaches micron level, supporting high-precision detection tasks.

Compact & Lightweight with Auto Splash-Proof Cover

Weighing only about 900g, with a length under 12cm, it’s ideal for lightweight robotic arms and confined welding spaces. The built-in splash-proof cover protects the lens during operation and closes automatically after scanning. Fully SDK-controllable.

Integrated Static & Dynamic Modes for End-to-End Welding

Static mode supports workpiece scanning; dynamic mode enables real-time weld seam tracking. Mode switching is handled via software, making a single camera suitable for the entire welding process.

Application Scenarios

The ViEye is widely applicable across industrial intelligent welding use cases, significantly improving productivity and reducing labor costs for users.

With the introduction of the ViEye Smart Welding Camera, Vizum brings a new breakthrough to intelligent industrial welding. Its superior precision, strong light resistance, compact design, splash-proof protection, and dual-mode functionality make it an ideal choice for customers in the smart welding sector. With ViEye’s support, industrial welding is set to reach a new level of sophistication.