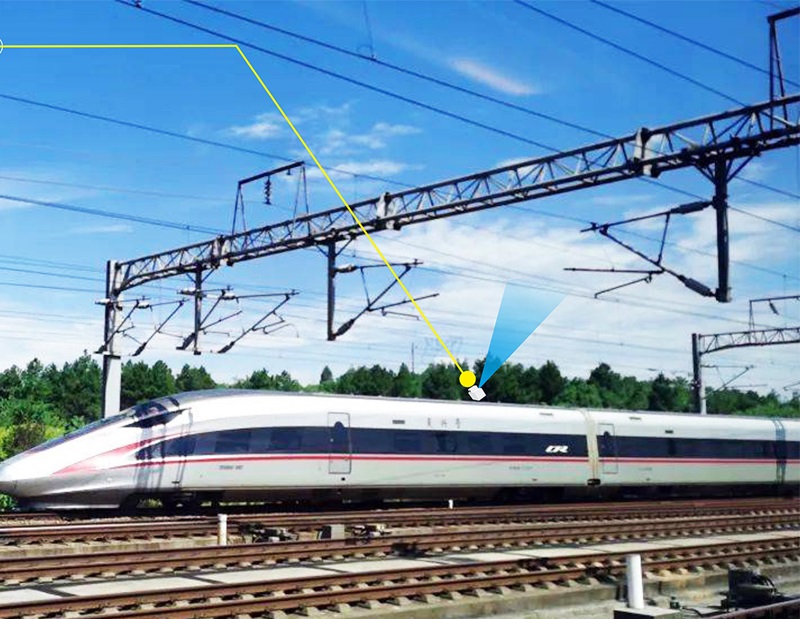

Recently, Vizum officially released its specialized visual sensor for detecting “hangers” in high-speed railway catenary systems. With exceptional detection performance, strong robustness, and high recognition accuracy, this sensor serves as a “guardian” of railway operational safety.

Supporting Railway Safety, Safeguarding Passenger Travel

By the end of 2021, China’s high-speed rail operating mileage exceeded 40,000 kilometers, and the total railway mileage surpassed 150,000 kilometers, ranking first in the world.

While marveling at the rapid development of China’s railways, one naturally wonders: with such an extensive railway network and massive passenger throughput, how is operational safety of trains and catenary lines ensured?

Regular safety inspections are a vital safeguard, enabling timely identification and resolution of potential issues to ensure train operation. 4C inspection focuses on the main components, structures, and parameters of the railway power supply network (also known as the catenary system). Hanger detection is a critical part of this. Hangers connect the messenger wire to the contact wire. Damaged hangers can shorten the service life of the pantograph or, in severe cases, endanger trains and passengers.

Traditionally, high-speed rail hanger inspection required workers to carry heavy grounding wires, walk along the tracks, and climb ladder cars to check bolts one by one. A full manual inspection along the entire line could take up to three years. Today, 4C inspection vehicles can take photos instead of manual checks, reducing the inspection time to once per quarter. However, workers still need to manually review vast numbers of images to identify issues.

Take the Beijing–Shanghai high-speed railway as an example: the catenary spans 1,318 kilometers. 4C inspection vehicles conduct quarterly inspections, collecting up to 3 million images in one round. Each image must be reviewed manually. If each person checks 8,000 images per day, 20 people working overtime would still need 20 days to complete the task. This immense workload and prolonged, monotonous review process require substantial manpower and can lead to fatigue-related oversight—posing safety risks. This has become a major challenge in 4C safety inspection.

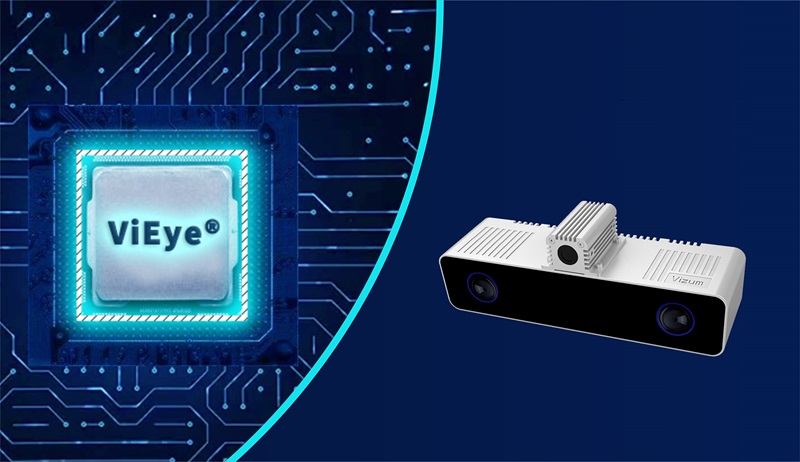

As early as 2019, Vizum began applying 3D stereo vision technology to the railway inspection sector and successfully developed solutions for rail and pantograph-catenary inspections. To address challenges in 4C inspection, Vizum developed a specialized visual sensor for high-speed rail hanger detection, reducing the number of inspection images by 75%, significantly cutting the manual review workload and shortening inspection cycles.

Smart Identification to Eliminate Redundant Data

Current 4C inspection vehicles use high-resolution planar cameras operating at high speed and frame rates to continuously photograph the catenary system along the railway line. In hanger detection, for instance, hangers appear every 6–8 meters on average. With a 2-meter camera field of view, two cameras covering a 500-kilometer segment would capture 500,000 images. However, only 130,000 of those images actually contain hangers—just one-fourth of the total. The rest are irrelevant.

Vizum’s specialized visual sensor uses binocular stereo imaging technology to quickly and accurately identify high-speed rail hangers. During high-speed vehicle operation, it provides real-time identification signals to trigger the planar camera to capture relevant images—eliminating unnecessary photos at the source and easing the burden of manual review.

Five Key Advantages Supporting Railway Safety

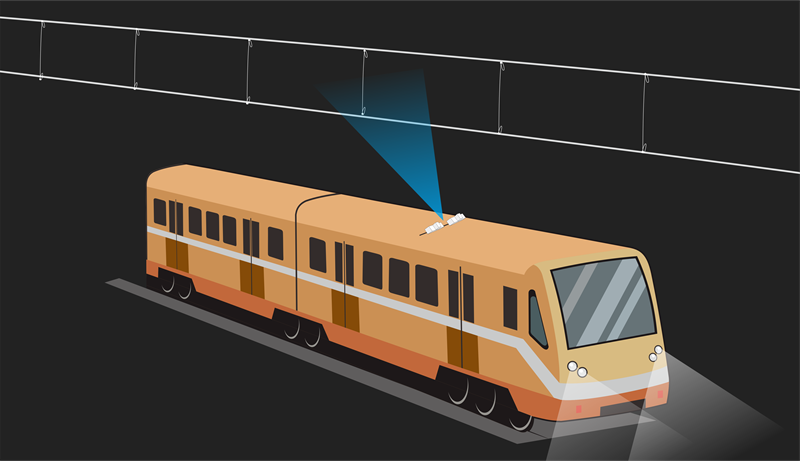

Rail inspection vehicles typically operate during night “maintenance windows” when trains are not running. Given China’s vast railway network, these vehicles face demanding requirements for environmental adaptability and operational stability. Traditional solutions often struggle with slow detection, poor reliability, and vulnerability to external interference—limiting their applications.

Vizum’s specialized visual sensor for hanger detection offers five major advantages—Speed, Precision, Stability, Scope, and Strength—perfectly suited for catenary inspection needs.

[Speed] Millisecond Response for High-Speed Capturing

4C inspection vehicles travel at 80–120 km/h, leaving only milliseconds for a hanger to appear in view. Vizum’s binocular stereo vision camera, equipped with high-performance hardware, can identify a hanger and trigger the planar camera to capture an image within 6 milliseconds.

[Precision] Laser Illumination, Immune to Low Light and Interference

The camera uses laser line illumination, eliminating reliance on ambient light. It accurately identifies hangers even during nighttime operation. Built-in noise filtering algorithms block stray light interference, preventing false triggers.

[Stability] Embedded Intelligence, Simple Operation

The stereo vision camera includes onboard processing, embedding hanger detection algorithms to output identification signals directly. No additional industrial computers are required—just mount the camera to the vehicle and perform simple setup to deploy.

[Scope] Wide Field of View and Depth of Field

With inherent wide FOV and depth-of-field advantages from binocular imaging, the camera excels in complex track environments such as zigzag routes, curves, and stations—ensuring reliable detection even in constrained spaces.

[Strength] Industrial Design for Harsh Environments

The camera features a reinforced metal casing, anti-vibration and corrosion-resistant design. Certified to IP67 standards and compliant with railway electromagnetic compatibility requirements, it operates within a -40°C to 70°C range—suitable for inspection nationwide.

Vizum’s specialized visual sensor enables 4C inspection vehicles to precisely capture catenary images, significantly reducing irrelevant image storage. This allows inspectors to complete full-line inspections efficiently using accurate images—mitigating risks and ensuring safe train operation.

China’s high-speed rail is not only expanding rapidly domestically but also gaining global recognition as a national symbol. Safety inspections are key to operational reliability. Vizum is proud to contribute to railway safety through its self-developed hanger detection sensor, and looks forward to delivering more innovations in the future. Stay tuned!