In recent years, China’s gypsum board production has maintained stable growth. From 2018 to 2019, the gypsum board industry continued to show vitality. In 2020, the total national output of gypsum board reached approximately 3.35 billion square meters. Gypsum board, made primarily from construction-grade gypsum, is a material known for being lightweight, high-strength, thin, easy to process, sound-insulating, heat-insulating, and fire-resistant. It is one of the new lightweight panel materials currently being heavily promoted. However, during production, various factors such as equipment, process, and raw materials often result in numerous defects—uneven dimensions, surface damage, surface holes, bubbles, uneven width, poor flatness, and non-perpendicular edges—severely affecting product quality and brand reputation. Meanwhile, relying on manual inspection wastes substantial labor resources and results in high costs, low efficiency, and minimal gains, which have become major obstacles to industry development.

Based on actual application needs and industry pain points, Vizum provides a complete hardware and software system solution for online, precise, and unmanned gypsum board inspection. Leveraging its proprietary stereo intelligent vision technology, Vizum has launched a gypsum board surface defect detection system. This system integrates AI, embedded edge computing, and machine learning to perform various surface inspections such as dimension defects, surface damage, and quantity defects. Through intelligent detection, it aims to reduce costs, improve efficiency, and enhance inspection accuracy.

Functional Applications

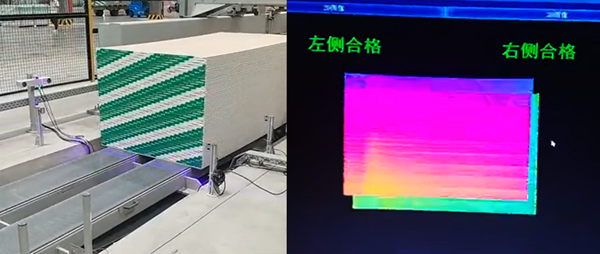

This system can detect surface defects such as damage, bubbling, denting, flatness, indentations, and edge issues. It can also measure the geometric dimensions of gypsum boards, including length, width, thickness, diagonal, and angle. During the outbound phase, the system can count the number of stacked boards, fulfilling full-process inspection requirements from production to warehousing.

Key System Highlights

Modular Design, High Flexibility

Each stereo camera can execute a single function or multiple functions via the server’s algorithm library. Camera layouts can be flexibly adjusted according to different scenarios.

High-Precision Online Real-Time Detection, Refined Data Management

Detection accuracy can reach ±0.1 mm with result data generated within seconds. It supports board speeds up to 2 m/s and allows real-time control during online inspection.

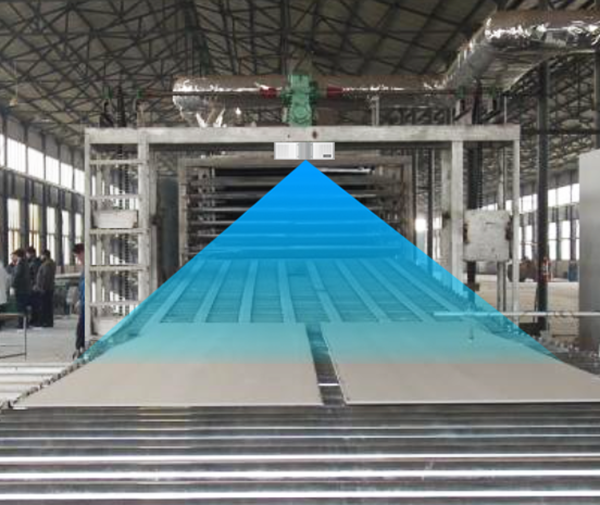

Large Depth of Field and Wide Field of View for Various Board Sizes

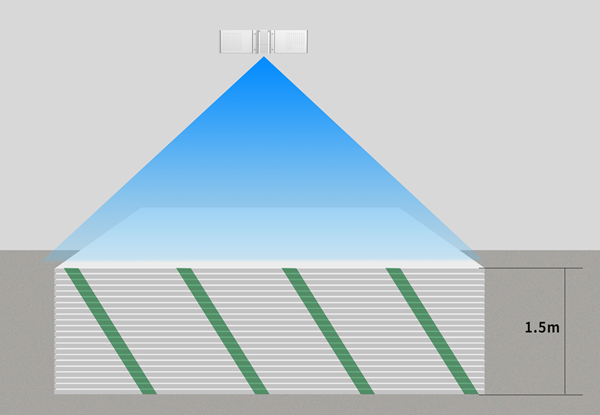

A single stereo camera can achieve a maximum detection field of view of 3 meters and support board heights up to 1.5 meters. Multiple cameras can be stitched together to accommodate larger inspection fields.

Flexible Integration, Fast System Connection

Supports various communication protocols including SDK, Modbus TCP, and TCP/IP for quick integration with customer information management systems.

Strong Adaptability for Complex Environments

Capable of high-precision real-time inspection for various types and surface colors of gypsum boards, with no fear of lighting conditions. Operates in both daytime and nighttime without the need for supplemental lighting. The cameras are designed to IP65 standards, enabling them to function reliably in dusty, vibrating, humid, electromagnetically noisy, and extreme temperature environments.

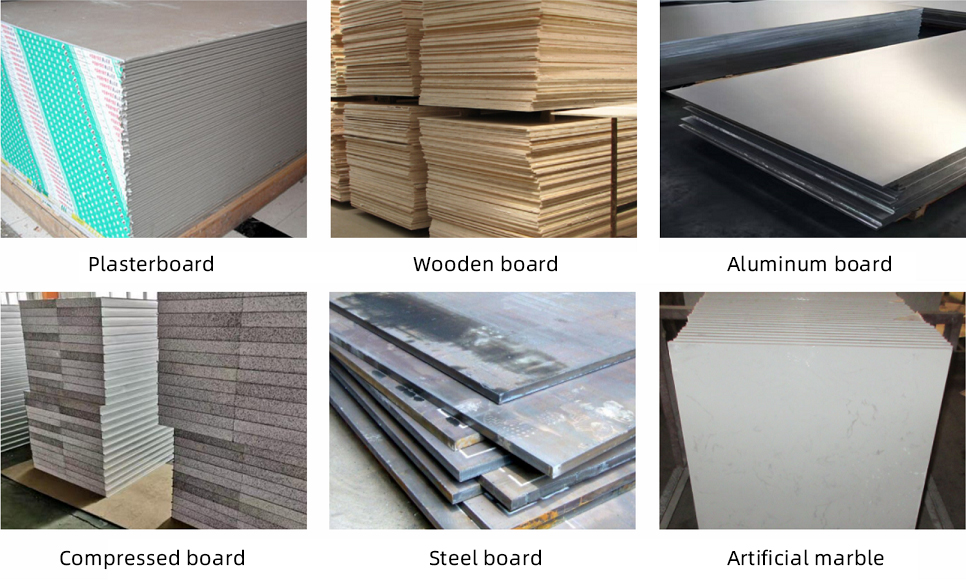

Through intelligent detection, this system significantly improves the accuracy and speed of gypsum board inspection, allowing for the collection and analysis of defect data, thereby supporting enterprises in optimizing and upgrading production capacity. The system also has strong scalability and general applicability—it can be used to inspect wood boards, compressed boards, aluminum sheets, steel plates, artificial marble, and more, helping traditional manufacturing industries achieve intelligent inspection, safe production, and high-quality quality control.