Belt Tear Detection System

System Overview

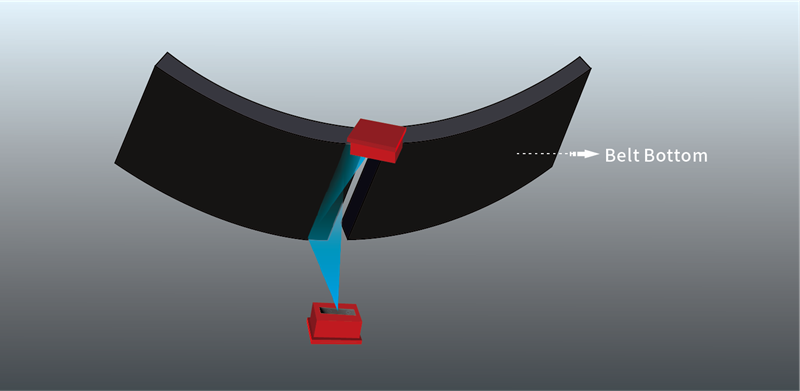

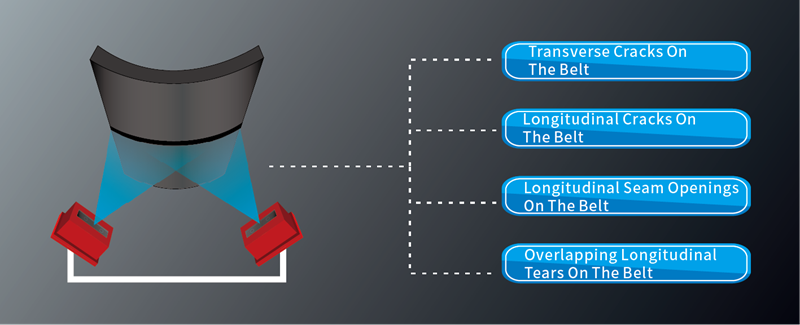

The Conveyor Belt Tear Detection System utilizes artificial intelligence and stereo vision technologies to perform real-time, online monitoring of high-speed coal conveyor belts. Through the deployment of a stereo intelligent camera installed beneath the belt, the system is capable of detecting various forms of abnormal belt tearing, including transverse cracks, longitudinal cracks, seam openings, and overlapping longitudinal tears. Upon detection, the system enables immediate automated control of the conveyor to prevent further damage. Built on a client-server (C/S) architecture, it supports the construction of a visualized data modeling platform, enabling 3D visualization of the belt, display of detection results, transport safety monitoring, and automated conveyor control. This comprehensive approach significantly improves the automation and intelligence of tear detection in mining conveyor operations.

System Features

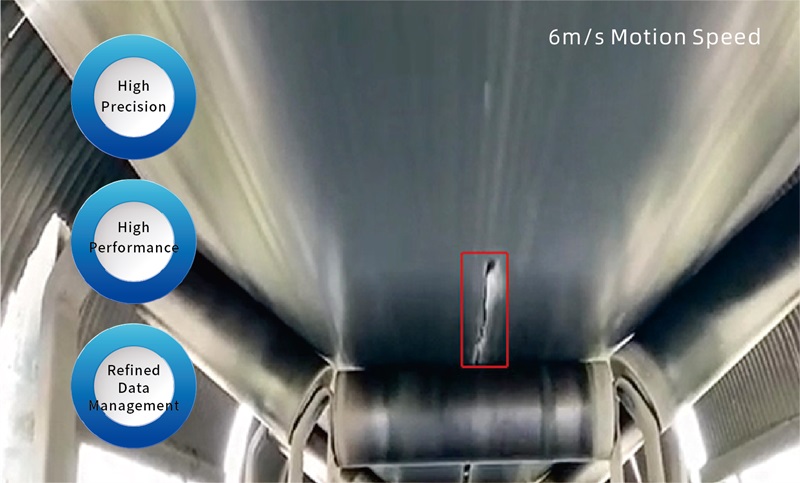

- Modular design, suitable for real-time detection in high-speed scenarios with motion up to 6 m/s.

- The camera is embedded with a high-performance image processing module, eliminating the need for an additional industrial control host.

- Factory-calibrated camera parameters, enabling fast deployment and easy setup.

- Provides a wide range of system integration interfaces, allowing direct connection to PLCs, inverters, and servers for quick and precise belt control.

- The system offers high precision, high performance, and refined data management.

- Industry-leading real-time performance and accuracy in high-speed dynamic detection.

- Millimeter-level detection precision, capable of detecting even the smallest cracks.

- The system meets the field-of-view requirements for various sizes of conveyor belts.

- The system software is generalized, allowing it to adapt to conveyor belt detection needs of different sizes.

- Multiple hardware systems can be integrated to expand the scanning field of view, meeting detection requirements at various positions.

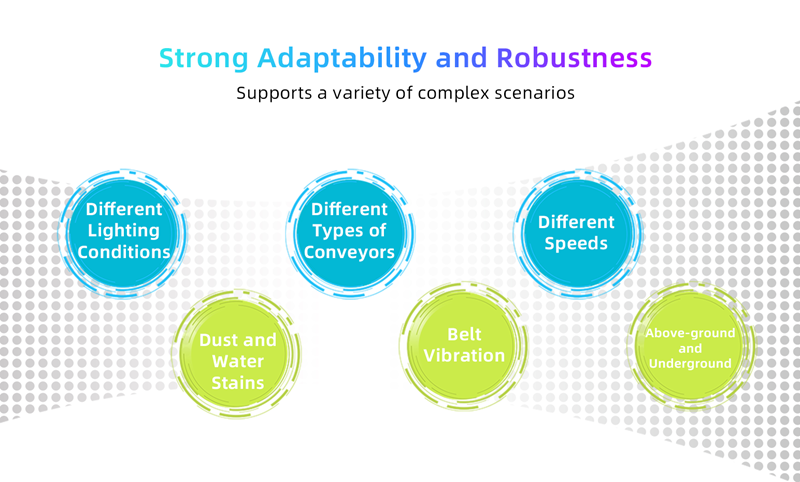

- The system features strong adaptability and robustness, supporting a variety of complex scenarios.

- It effectively suppresses light and shadow interference, ensuring normal operation in indoor, outdoor, dim, and nighttime environments without the need for additional lighting.

- Real-time detection is supported for various types of conveyors, including flat, U-shaped, and V-shaped designs.

- The system adapts to variable-speed conveyor scenarios, with the option to connect external pulse encoders and proximity switches for real-time synchronization with conveyor speed, maintaining detection accuracy.

- It ensures high-precision detection in environments with dust, water stains, and other challenging conditions on the belt surface.

- The system adapts to vibration during the belt transportation process, with algorithms for automatic vibration adjustment.

- Explosion-proof hardware for underground applications and industrial-grade hardware platforms for above-ground applications are provided, meeting the requirements of different operational environments.

System Functions

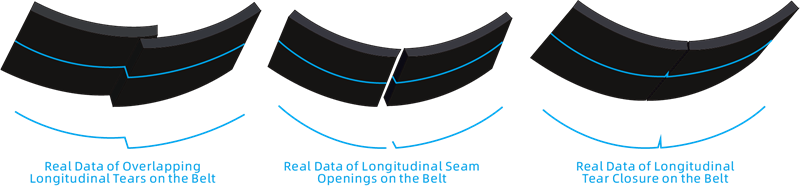

Belt Tear Safety Monitoring:Installed at the bottom of the belt, the system monitors the height variation and continuity of the point cloud from the 3D model of the belt to detect lateral and longitudinal belt tears during high-speed motion. It triggers alarms when abnormalities are detected. The system can identify various types of belt tears, including transverse cracks, vertical cracks, longitudinal seam openings, and overlapping longitudinal tears.

Belt Automatic Control:

The system can automatically control the speed variation and start/stop functions of the belt based on the result data signals.

Detection Accuracy: ≤ 3mm

Supported Motion Speed: 6m/s

Communication Protocol: Supports Modbus TCP for quick integration.

Belt Tear Detection Principle:

The system allows for the presetting of threshold values for the actual width, length, and depth of belt tears.

By analyzing the height variation and continuity of the 3D point cloud data from the scanned belt model, it measures the length, width, and height of the tear areas.

The measured dimensional data is then compared to the predefined threshold values to determine whether there is any abnormal tearing.