Conveyor Flow Volume Monitoring System

System Overview

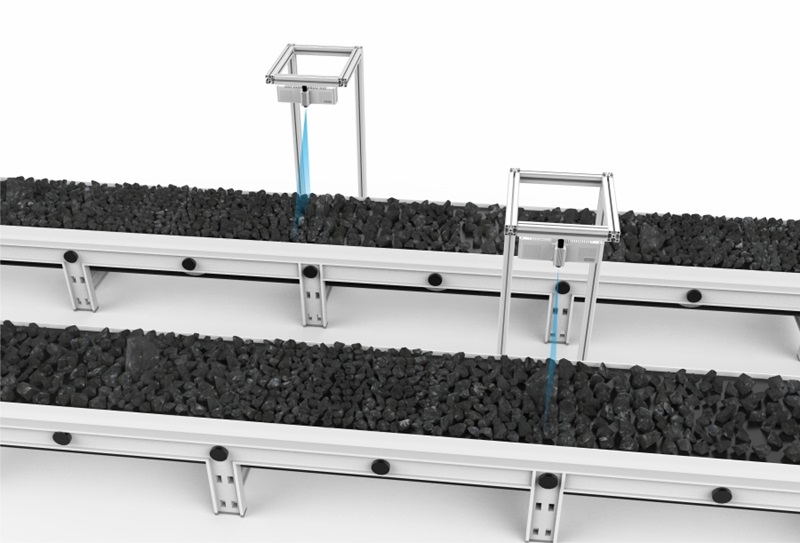

The Conveyor Flow and Volume Monitoring System uses Vizum’s self-developed stereo vision technology, allowing real-time volume data collection of objects on moving conveyors via the stereo camera. It requires no modifications to the conveyor environment; simply fixing the camera above the conveyor is enough to set up the system. This system enables various intelligent applications, such as conveyor speed control, production big data management, and outbound flow control. It is suitable for flow and volume monitoring on moving conveyors in industries such as coal, mining, salt, stone, cement, logistics, and agriculture.

System Functions

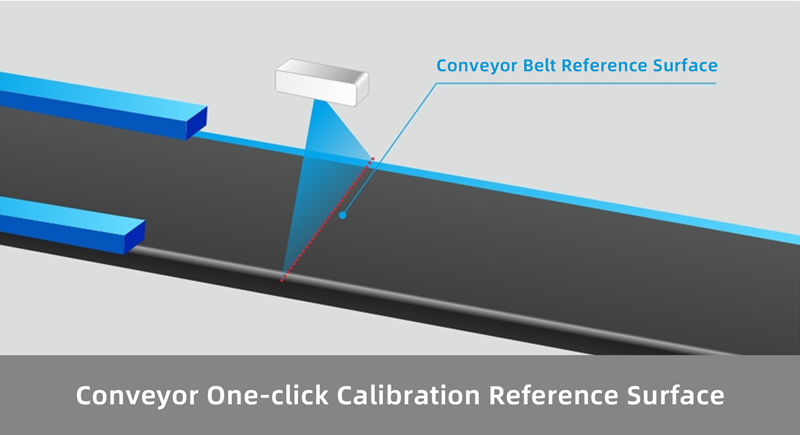

The system can calibrate the conveyor’s bottom surface as the reference plane for volume measurement with a single click, applicable to all types of conveyors, including flat conveyors, U-shaped conveyors, and V-shaped conveyors.

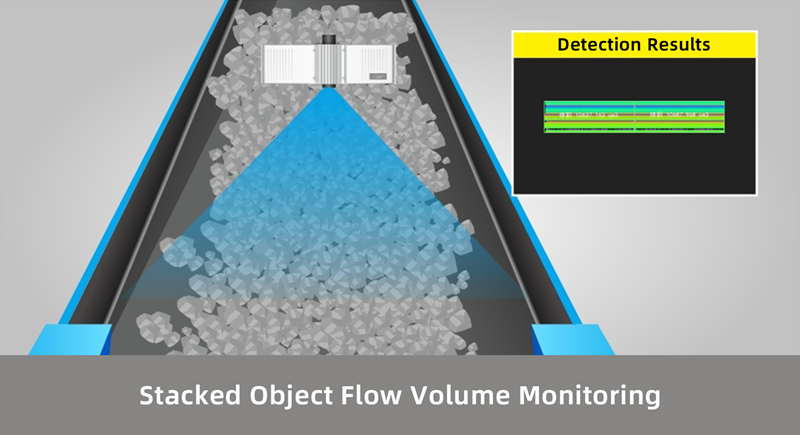

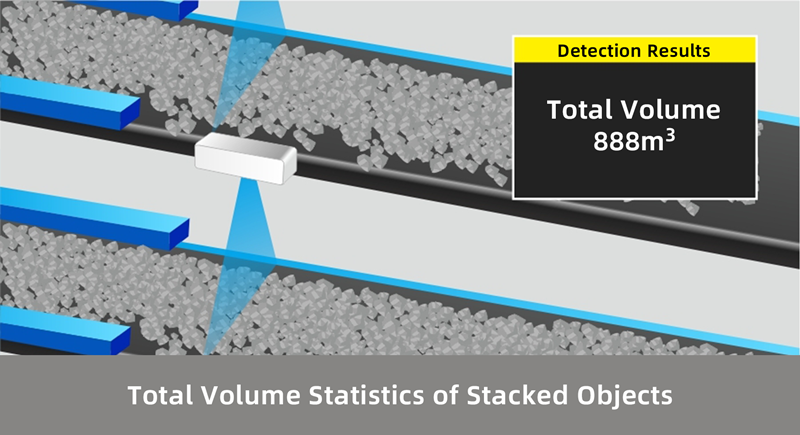

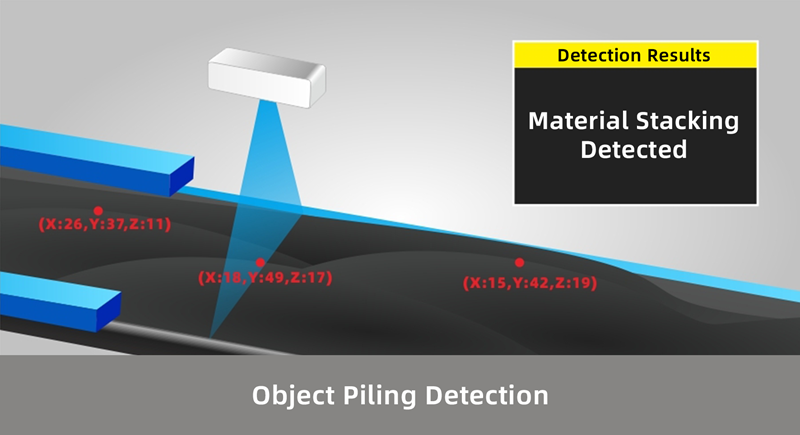

The system can monitor the flow volume of stacked objects on the conveyor within a unit of time.

The system can perform contour surface integral volume measurement for individual separated objects on the conveyor.

The system can measure the maximum length, width, and height dimensions of individual separated objects on the conveyor.

System Features

- Embedded Algorithm: Enables direct volume and flow data output at the camera end without requiring an additional industrial control host.

- Real-Time Detection for High-Speed Motion: Supports conveyor speeds up to 6 m/s for real-time monitoring.

- High Performance: Stereo camera acquisition, processing, and transmission time is under 20 ms, with measurement accuracy reaching ±(0.1 mm–3 mm).

- Wide Field of View: A single camera covers up to 3 m in width; multiple cameras can be seamlessly stitched to accommodate larger conveyor widths.

- Factory Calibration: Stereo cameras are pre-calibrated with epipolar geometry, enabling direct plug-and-play installation on-site.

- Multiple Trigger Modes Supported: Compatible with software trigger, level trigger, and pulse trigger for flexible system integration.

- Industrial-Grade Design: Built with rugged industrial-grade components, featuring aviation connectors and IP65 protection rating.

Application Scenario Adaptability

- Ambient Light Adaptability: Effectively suppresses light interference and shadows; operates reliably in indoor, outdoor, low-light, and nighttime environments.

- Compatibility with Various Conveyor Types: Supports real-time monitoring on straight, U-shaped, and V-shaped conveyors.

- Adaptation to Variable-Speed Conveyors: Equipped with a speed-tuning interface, supports external pulse encoders and speed sensors to maintain volume measurement accuracy in real time.

- Vibration Compensation: The system self-adjusts to conveyor vibration frequencies to prevent accuracy errors caused by mechanical shaking.

- Inclination Compensation: Supports one-click calibration for inclined conveyor surfaces, treating them as the volume measurement reference plane.

- Surface Reflectivity Adaptability: Accurately detects reflective surfaces, including wet, glossy, or dark-colored objects with strong light absorption.

- Dust Environment Tolerance: Utilizes filtering algorithms to eliminate point cloud noise caused by dust, ensuring high-precision measurements.

- Support for Stacked and Randomly Oriented Objects: Detects various object shapes and orientations in real time, regardless of stacking method.

- Color Adaptability: Capable of detecting mixed-color objects, including black-and-white and multi-color items simultaneously.

- Temperature Resilience: Operates reliably from -20°C to 70°C, suitable for diverse regional climates and environmental conditions.

- No On-Site Modification Required: Cameras can be mounted directly above conveyors without altering existing infrastructure or production lines.

System Applications

The Conveyor Flow and Volume Monitoring System features applicability and universality. It can be applied to conveyor belt scenarios in various industries without changing the core algorithm, mainly including but not limited to multiple industry fields such as coal, mining, salt industry, sand and gravel, cement, logistics, and agriculture.