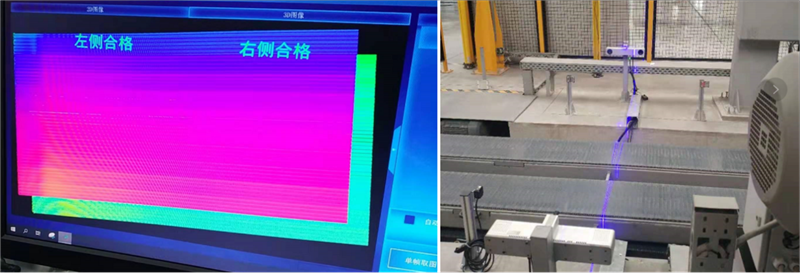

Gypsum Board Surface Defect Detection System

System Overview

Gypsum board is a material made primarily from building gypsum. It is lightweight, relatively strong, thin, easy to process, and offers excellent soundproofing, insulation, and fire-resistant properties. It is one of the new lightweight board materials currently being developed. During production, due to various factors such as equipment, processes, and raw materials, gypsum boards often exhibit defects, such as uneven dimensions, surface damage, surface holes, bubbles, uneven width, poor flatness, and non-vertical edges. These defects severely impact product quality, harm the reputation of enterprises, and waste significant labor resources for inspection, leading to high costs and low efficiency.

The Gypsum Board Surface Defect Detection System utilizes a stereo vision technology system, combined with artificial intelligence, embedded edge computing, and machine learning technologies. It can perform real-time three-dimensional model reconstruction of the gypsum board’s surface and side in its original scale. By comparing it with a standardized 3D model, the system can detect various defects, including size, damage, and count-related defects on the surface. The system features intelligent terminals, high precision, strong real-time capabilities, modularity, fast implementation speed, and strong environmental adaptability. This detection system can be applied across various stages of gypsum board production, including production, transportation, and warehouse outflow, to enable intelligent inspection.

System Functions

Appearance Defect Detection:

Damage Detection: Detection of surface and edge/chipped damage on the gypsum board.

Bubble Detection: Detection of any raised bubbles on the gypsum board surface compared to the standard surface.

Dents Detection: Detection of any depressions or indentations on the gypsum board surface compared to the standard surface.

Flatness Detection: Detection of overall flatness of the gypsum board to ensure it meets standards.

Indentation Detection: Detection of continuous indentations on the gypsum board surface.

Edge Detection: Detection of the verticality of the edges of the gypsum board.

Dimension Measurement:

Board Length Measurement: Measurement of the gypsum board length to ensure it meets the standard.

Board Width Measurement: Measurement of the gypsum board width to ensure it meets the standard.

Diagonal Measurement: Measurement of the gypsum board’s diagonal length to ensure it meets the standard.

Board Thickness Measurement: Measurement of the gypsum board thickness to ensure it meets the standard.

Edge Angle Measurement: Measurement of the gypsum board’s edge corners to ensure they form right angles.

Quantity Counting:

Stacked Gypsum Board Quantity Counting: Verification of the correct quantity for each stack of gypsum boards during the outbound stage.

Individual Gypsum Board Production Quantity Counting: Statistical management of the production quantity of gypsum boards.

System Features

- Modular Design: Each stereo camera can perform single or multiple functions via the server algorithm library, and the hardware layout of the stereo cameras can be adjusted anytime according to different scenes.

- Ultra-High Performance: Detection accuracy can reach up to ±0.05mm, with result data generated within seconds.

- Open Data Output Interface: Fast integration with customer information management systems, supporting standard communication protocols for quick data result transmission.

- Multi-Platform Support: Supports both Windows and Linux platforms.

- Various Trigger Modes: Supports soft trigger, level trigger, pulse trigger, and other working trigger modes; applicable for both constant speed and variable speed detection scenarios.

- Fast Object Motion Detection: Can meet the 1mm accuracy requirement within a speed range of 2m/s.

- Flexible Detection Area Setup: Easily filter out areas that do not require detection, providing flexibility and convenience.

- Large Field of View and Depth of Field: The maximum detection field of view can reach up to 3m, supporting gypsum board detection at a height of 1.5m.

- Strong Environmental Adaptability: Effectively suppresses light and shadow interference, ensuring normal use in both indoor and outdoor environments, even in dim conditions.

- Industrial Grade Design: Better suited for harsh environments such as dust, vibration, humidity, electromagnetic interference, and extreme temperatures.

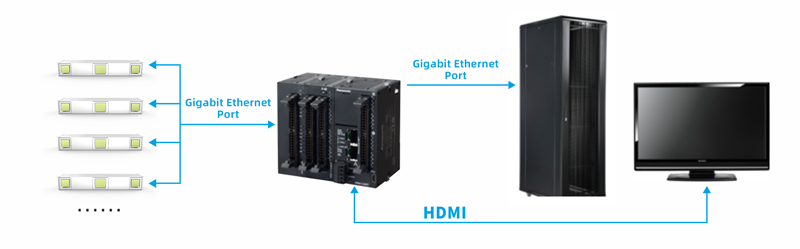

System Communication Diagram

The stereo camera is installed above or on the side of the conveyor belt for application, generating proportional point cloud 3D coordinate outputs of the gypsum board. The results are calculated through the algorithm library on the server side. Data can be transmitted to third-party systems via the gigabit network interface and visualized through a display interface for data management and remote camera debugging.

System Applications

The defect detection system has rich industry scalability and can be used to detect materials such as gypsum boards, wooden boards, compressed boards, aluminum plates, steel plates, and artificial marble.