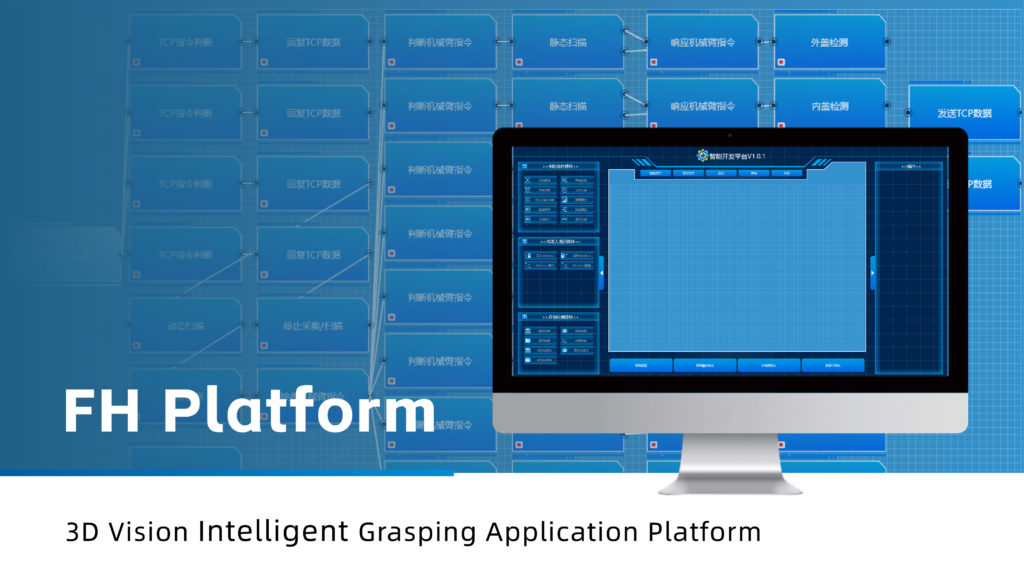

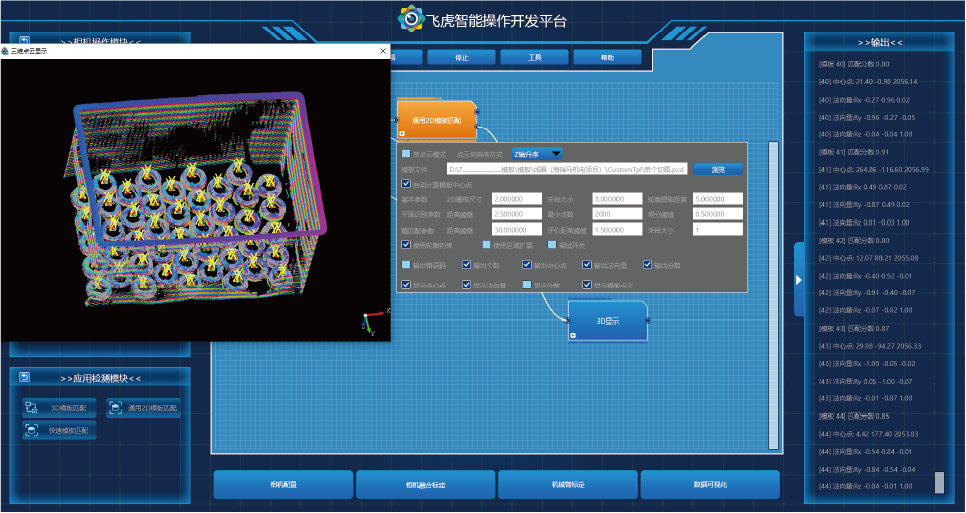

The 3D Vision Intelligent Grasping Application Platform is built on a highly modular system architecture, with 3D stereo vision technology at its core. It provides visualized packaging and presentation of functional and algorithm modules such as image perception, image cognition, 3D modeling, positioning and guidance, pose estimation, hand–eye calibration, interface integration, and signal triggering. Users can flexibly call required modules from the built-in algorithm library based on their needs and independently complete tasks using the integrated Vizum’s camera system.

Solution Features

High-Speed, High-Precision 3D Scanning

Accurate 3D scanning forms the foundation of intelligent grasping. The FH Platform uses the “3D Modeling” module to complete object scanning. Once 3D data is obtained, image processing continues through subsequent modules. High speed: instant scan and output; High precision: sub-millimeter accuracy; Multi-output and parallel processing.

Drag-and-Drop Interface, No Programming Required, Fast Deployment

A user-friendly, drag-and-drop graphical interface enables fast setup without any programming knowledge.

- Build workflows using drag-and-drop modules

- Setup completed in under five minutes

- Ready-to-use development flow

- Remote updates supported for seamless development

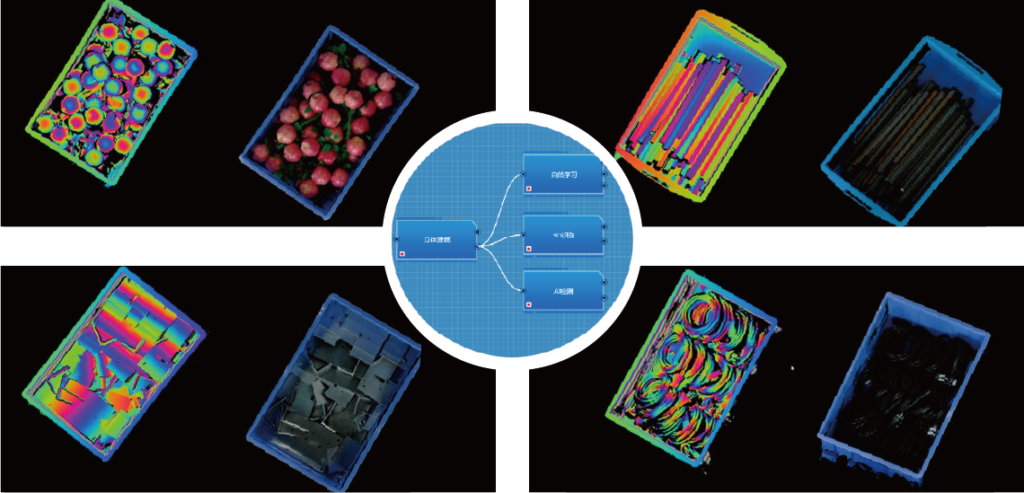

Natural Learning, No Training Needed, Grasp Anything

Whether dealing with regular objects, flexible materials, or complex shapes, the FH Platform can dynamically adjust its grasping strategy to ensure precise and efficient task execution.

- Supports detection of various object types

- Flexible multi-dimensional parameter settings

- Intelligent terminal-based fast recognition

- Full coverage across multiple industries and object types

All-in-One Integration: Camera, Algorithm, Robot Arm

The platform integrates the camera, software, and robotic arm control into a single system, streamlining operations, simplifying maintenance, and reducing development and operational costs.

- End-to-end development flow

- Adaptable to diverse grasping scenarios

- Reusable modules and parallel workflows

- Real-time data visualization

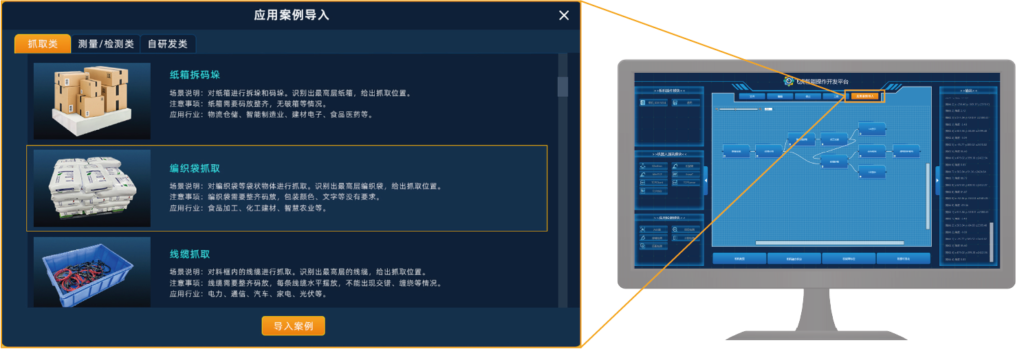

One-Click Import of Application Cases for Rapid Deployment

Similar workflows can be quickly built and reused, greatly simplifying the process of creating application flows. This enhances work efficiency and enables fast response to business needs.

- Grasping case templates

- Measurement/inspection case templates

- Custom-developed case templates

- Cloud synchronization supported for all case types

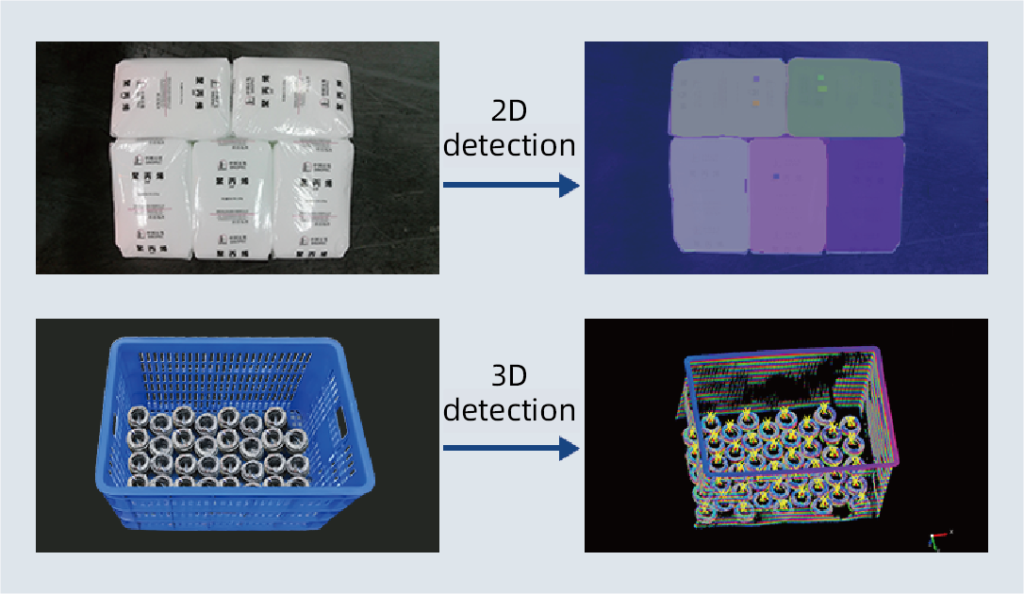

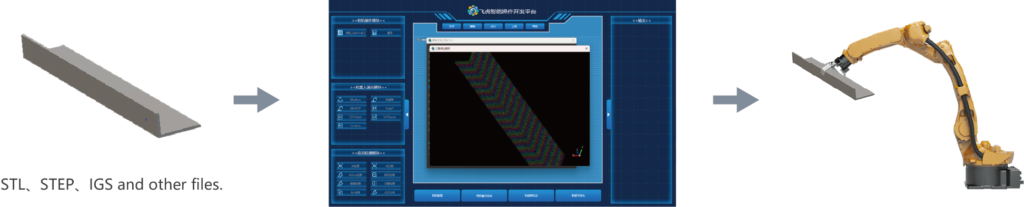

Template Import and Fast Object Recognition

Supports importing object models and generating grasp templates on demand, allowing for quicker identification and grasp point generation.

— No manual modeling required — Quickly extract key object features — Faster recognition speed

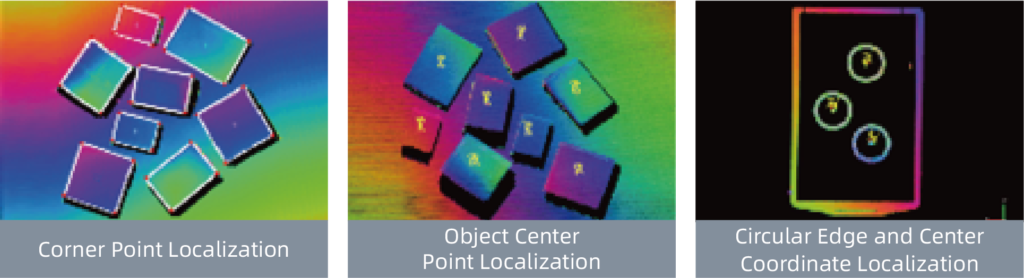

Accurate Object Localization and Versatile Grasp Point Selection

Based on object shape, the platform provides precise grasp point poses and supports multiple grasping point candidates, selecting the optimal one.

Compatible with Dozens of Industrial Robot Brands

Fully compatible with major domestic and international robotic arms including ABB, Yaskawa, KUKA, Nachi, Panasonic, FANUC, Kawasaki, AUBO, Han’s Robot, STEP Electric, EFORT, Paiten, Rokae, Qianjiang Robot, Estun, Siasun, JAKA Robotics, Borunte, and MoCa. and more.

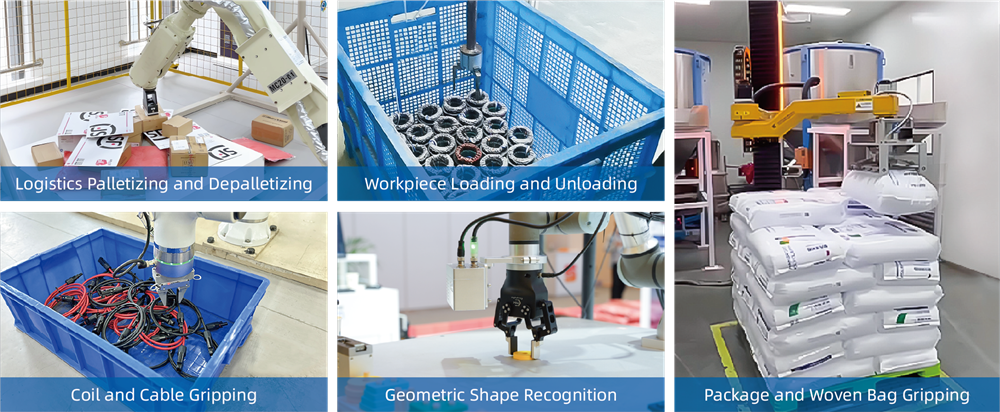

Application Scenarios